Rendimiento y características:

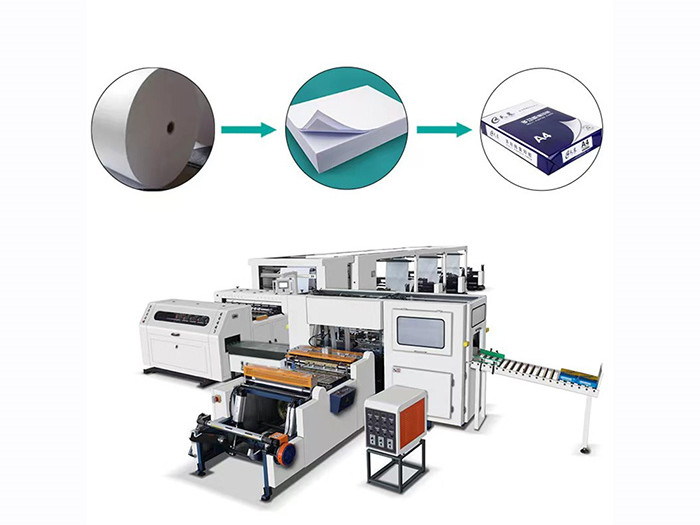

Esta máquina es adecuada para cortar todo tipo de papel, autoadhesivos, compuestos de papel y plástico, telas no tejidas y otros materiales de embalaje de tambores grandes. Esta máquina adopta un servomotor para controlar el corte de longitud fija. El sistema de transmisión adopta sensores neumáticos, fotoeléctricos y otros controles centralizados. Esta máquina integra luz, electricidad y gas. Tiene las ventajas de un funcionamiento sencillo, alta precisión de corte, estabilidad mecánica y bajo nivel de ruido. (Se puede seleccionar alimentación neumática) regulación de velocidad de conversión de frecuencia del motor, conteo automático, apagado de alarma, función de ajuste automático de tensión de conicidad de partículas magnéticas. En la actualidad, es un equipo ideal para el corte de bobinas a gran escala con alta calidad en China.

1. Regulación de velocidad de conversión de frecuencia del host, sistema de control de pantalla táctil PLC Panasonic, conteo automático, determinación automática de longitud, estacionamiento de alarma, control automático y otras funciones

2. El marco adopta una estructura de placa de acero de 16 mm, la base del cortador transversal adopta una estructura pesada fundida y el rodillo guía adopta un rodillo guía de aleación de aluminio de equilibrio dinámico.

3. La tracción de posicionamiento de la transmisión adopta la estructura del eje de transmisión del sistema servo, y el modo de tracción de alimentación es en el que el motor impulsa la rueda dentada para impulsar y traccionar el eje de goma.

4. Esta máquina es un equipo de corte transversal en línea ideal con alta precisión y velocidad.

一、 Main technical parameters:

|

Model |

MDH-16100 |

|

Max.Diameter of Unwinding |

φ1400mm |

|

Max. Cutting Width |

1600mm |

|

Cutting Length |

A4/A3(297*210mm,297*420mm) |

|

Cutting Speed |

50-200times/min *2 |

|

Paper GSM |

60-120g |

|

Cutting Precision |

±0.2mm |

|

Ream Height(mm) |

500pcs |

|

Total Power |

约 21kw |

|

Machine Weight |

9000kg |

|

Compressed air(Mpa) |

(Customer's own responsibility) |

|

Main power source |

380V/50HZ, 3phase 4 wires

|

|

Machine Size(L*W*H) |

17000×2710×2000mm |

二、Host part

(1) The frame adopts 16 × high-quality steel plate structure

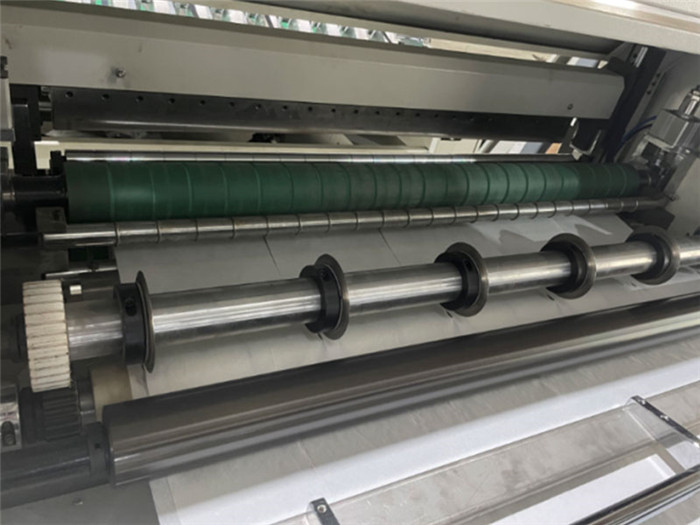

1).Traction device:

(1) Structure type: active traction passive compression type

(2) Traction base adopts casting structure (1 set)

(3) The traction roller adopts rubber roller (specification:10 pieces φ85 × 1150mm)

(4) The pressing mode is controlled by air cylinder

(5) The transmission guide roller adopts aluminum guide roller (specification:52 pieces φ75× 1150mm)

(6) The driving guide roller can be tensioned up and down

(7) The motor adopts three-phase asynchronous variable-frequency motor 1.5kw (Shanghai Dedong) (4set)

(8) The frequency converter adopts geetec 1.5KW (4 set)

(9) The feeding adopts floating arm mechanism to store and buffer materials.

(10) Pneumatic traction is adopted for floating up and down tension

(11) Floating guide roller: aluminum guide roller (specification: 12 pieces φ75 × 1150mm)

(12) The whole feeding mechanism is intelligently controlled by displacement sensor.

2)Feeding mechanism:

1. Adopt servo control positioning mode actively

2.5.5kw NVIDIA servo motor, driver (1 set)

3. The industrial control system of the whole machine adopts the driving mode of digital industrial control system: the main motor drives the positioning of the driving roll

4. The transmission adopts synchronous belt and synchronous wheel transmission mechanism

5. The feeding roller adopts the structure of light rubber roller

6. Use conveyor belt to transport to the finishing area

3)Cutting device:

(1) Cutting method: the lower knife is fixed, and the upper knife actively cuts

(2) The cutterbed adopts cast heavy structure:

(3) Linear guide rail (2 pairs)

(4) Oil container (2 pcs)

(5) Lubricating oil can be recycled

(6) The upper and lower round knives adopt imported balanced steel cutting tools (8 pairs)

(7) Cutter (specification thickness × wide × Length: 15 × eighty × 1150mm) (Shanghai joint venture) (2 pairs)

(8) Operation mode: manually adjust the tool position at will

(9) Main transmission mode: the main motor drives and matches the transmission machine to drive the eccentric wheel linkage connecting rod to move the cutter back and forth

(10) The main motor adopts frequency conversion and speed regulation motor Shanghai (3KW)

(11) The frequency converter adopts geetec (1.5KW, 1 set)

(12) The transmission adopts synchronous wheel transmission mechanism

(13) Eccentric (2 sets)

(14) Connecting rod (2)

(16) Discharging device; There is a shaft discharging rack for pneumatic feeding, standard configuration; 1pc air inflation shaft for 1600mm, 2 cylinders 160*300=2, 1 set of magnetic particle 10kg, 1 set of deviation correction system,4 sets in total

3. Electrical control part: (the control is connected in parallel with the host part) the whole machine is controlled by Panasonic PLC industrial control system, and the touch screen is Taiwan Willem)

(1) The control system of the machine is roughly controlled by the host.

(2) Host control: including main motor control, traction control, feeding control and cutting control.

(3) Floating control: it has a wide speed range and good performance no matter at low speed or high speed.

(4) With electronic meter counting; Alarm shutdown; Automatic length fixing, point in and point out functions.

(5) Chint is selected for the above electrical components; The switch adopts Schneider brand

4. Supporting facilities: (the user is responsible for it)

(1) Power supply: three-phase four wire air switch: voltage 380V / 50Hz

II Machine part location