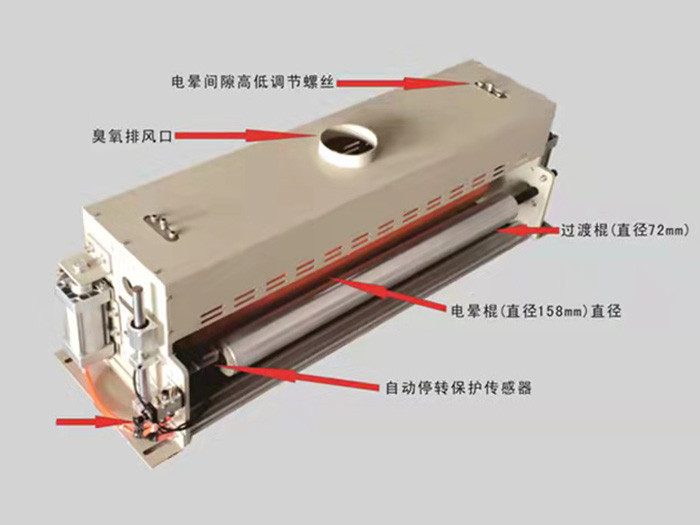

Closed corona discharge rack (single side opening, optional pneumatic opening):

600-1200mm

Optional power: 3kw-4kw (Corona roller)Φfifty-five

Processing speed: 5-100m / min

Treatment width: 600-1200mm

Processing surface: double-sided single punch / single-sided double punch

Size: 300 * 300 * 870-1470mm

Correct selection of corona generator:

Electronic surface polarization treatment equipment is also known as electronic impact machine, corona machine and electric spark machine. Electronic plastic surface polarization treatment is an essential process in the plastic printing industry before film blowing, compounding, coating, vacuum aluminum plating and plastic printing. Surface polarization treatment is also widely used in paper printing, printing and dyeing and cable manufacturing. Although the volume and value of surface polarization treatment equipment are "insignificant" compared with other mechanical equipment such as film blowing machine, printing press and compound machine, its quality assurance role in these process flows is well known by every production unit. It can be said that there is no modern plastic printing technology without electronic surface polarization treatment equipment. As the electronic surface polarization treatment equipment is an electronic equipment, there are many production units and a mixture of good and bad people. It is difficult to distinguish the advantages and disadvantages only by the self publicity of the manufacturer. When users choose electronic surface polarization treatment equipment, they do not know how to select and judge the technology and performance of various equipment. If it is identified with reference to the method described below, a satisfactory electronic surface polarization treatment equipment can be selected.

1. Volume and specific weight

In the electronic surface polarization treatment equipment with the same power or treatment width, the smaller the volume and the lighter the weight, the higher the technical content and the more advanced and reliable the technology. Because the essence of electronic surface polarization treatment equipment is high-power AC high-frequency inverter power supply. The first generation of thyristor inverter uses low-voltage inverter technology. Many bulky and bulky power frequency transformers are used in the equipment, and the inverter frequency is low. The pulse transformer used for inverter is large and bulky. For example, the weight of a kilowatt of electronic surface polarization treatment equipment is 20 ~ 30 kg. Therefore, the volume of thyristor electronic surface polarization treatment equipment is huge and bulky. The second generation of electronic surface polarization treatment equipment gets rid of the power frequency transformer, uses transistors or Gbit power devices, directly inverts the power frequency power supply, improves the inverter working frequency, reduces the volume of the inverter pulse transformer, and greatly reduces the overall volume and weight of the electronic surface polarization treatment equipment compared with the thyristor type equipment. For example, the weight of a kilowatt of electronic surface polarization treatment equipment is about 8 ~ 16 kg. The third generation of electronic surface polarization treatment equipment adds a microprocessor (single chip microcomputer) on the basis of the second generation, which improves the energy conversion efficiency and working frequency of the equipment compared with the second generation, and further reduces the volume and weight of the whole machine. For example, the weight of the third generation one kilowatt electronic surface polarization treatment equipment is only 3 ~ 5kg. In terms of volume, the volume ratio of the third generation equipment is about: the volume of the first generation equipment: the volume of the second generation equipment ≈ 3 to 5:1, the volume of the second generation equipment: the volume of the third generation equipment ≈ 2 to 3:1. Whether the whole structure of the electronic surface polarization treatment equipment is simple and reasonable also represents the technical level of the equipment and the maintainability of the equipment. Because the essence of electronic surface polarization treatment equipment is high-power AC high-frequency inverter power supply, its failure rate is higher than that of other equipment. After purchasing the equipment, users must consider the maintainability of the equipment after failure. The volume of the first generation thyristor type electronic surface polarization treatment equipment is huge and bulky. For example, the volume of a 3000 Watt equipment can reach the size of a household vertical cabinet, and the weight can be nearly more than 100 kilograms, with complex circuit connections. Once the equipment fails, it can only be maintained by professional technicians or on-site service of the manufacturer. For units that do not have the conditions for maintenance, they can only look at the machine and sigh. The modern third generation microprocessor-based electronic surface polarization treatment equipment has small, simple and reasonable structure because of its high integration of control circuit, strong automatic control and detection ability and high energy conversion efficiency. For example, the volume of a 3000 Watt device is only half the size of a computer host. Coupled with its modular structure (usually 2 ~ 3 modules inside), it is very convenient and easy to maintain. Even if the equipment fails, the problem can be solved in time as long as the relevant modules are obtained or purchased from the equipment production unit through express mail.

2. Listen to the sound, watch the spark and measure the effect

After subjectively evaluating the appearance and structure of the electronic surface polarization treatment equipment, the host can be connected with the discharge rack for power on detection. Connect the power supply and the equipment shall work normally. Corona "discharge" will appear between the silicon rubber roller and the metal electrode on the discharge frame, and the corona discharge will gradually be uniform as the silicon rubber roller is heated (5 ~ 10 minutes). Due to the great difference of working frequency of electronic surface polarization treatment equipment in different years, there are also obvious differences in corona discharge phenomenon and sound characteristics of the equipment. The working frequency of silicon controlled electronic surface polarization treatment equipment is low, about 5KHz. The corona discharge spark is thick, "arc" will extend far beyond the edge of metal electrode, and the arc color is blue and red. When the requirement of the surface polarization dyne value of the film treatment is high, increasing the treatment power will lead to the perforation of the film, reduce the barrier of the film and make the reverse side of the film also have a high dyne value to the decline of welding fastness. When working, the equipment will also send out strong sharp screams. The third generation of microprocessor controlled (intelligent and digital) electronic surface polarization treatment equipment generally has a high working frequency, about 14 ~ 25 kHz. The corona discharge spark is fine and uniform, "arc" is basically concentrated near the metal electrode, and the arc color is blue and white. No sharp scream can be heard when the equipment is working, only the rustling sound emitted by the corona discharge of the discharge rack can be heard. When the requirement of the surface polarization dyne value of the film treatment is high, the treatment power can be increased and the barrier property of the film will not be reduced. The corona discharge characteristics of the second generation electronic surface polarization treatment equipment and its working frequency are generally between them. Of course, the use effect of electronic surface polarization treatment equipment should be finally judged by the measurement of treatment effect. Under the condition of the same width and treatment effect, the third generation microprocessor type electronic surface polarization treatment equipment saves 1.5 ~ 2.5 times energy than the first generation thyristor type electronic surface polarization treatment equipment.

3. Test protection, variable conditions and touch heat

When selecting electronic surface polarization treatment equipment, pay special attention to the reliability of the equipment. Generally, the methods of trial protection, changing conditions and touching heat can be used to evaluate the quality and early reliability of the equipment.