Rendimiento y características:

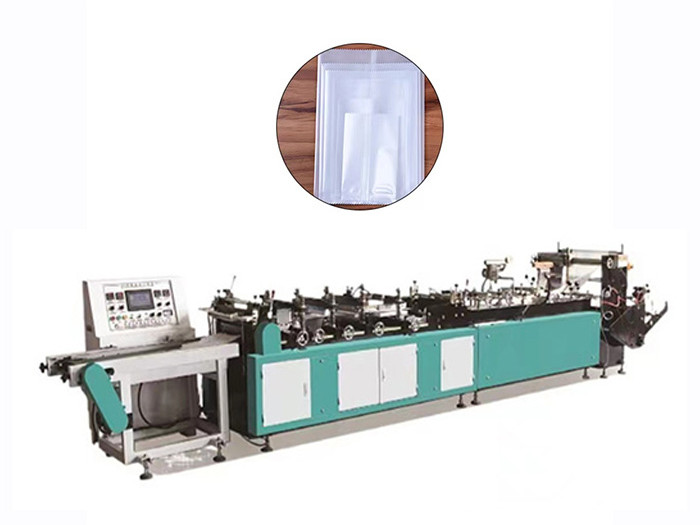

La máquina es adecuada para sellado automático, sellado inferior y corte de bolsas compuestas de embalaje flexible. Adopta control automático por computadora, control de servomotor, regulación de velocidad de conversión de frecuencia, seguimiento fotoeléctrico, conteo de trabajo, control automático de temperatura, estacionamiento alto, 2 dispositivos de planchado y sellado, tecnología de sellado y nivelación firme. (Se puede agregar troquel de punzonado y apertura de corte, dispositivo de sellado de bolsas de película única según los requisitos del usuario).

Machine details:

|

Machine part |

Electric part |

|

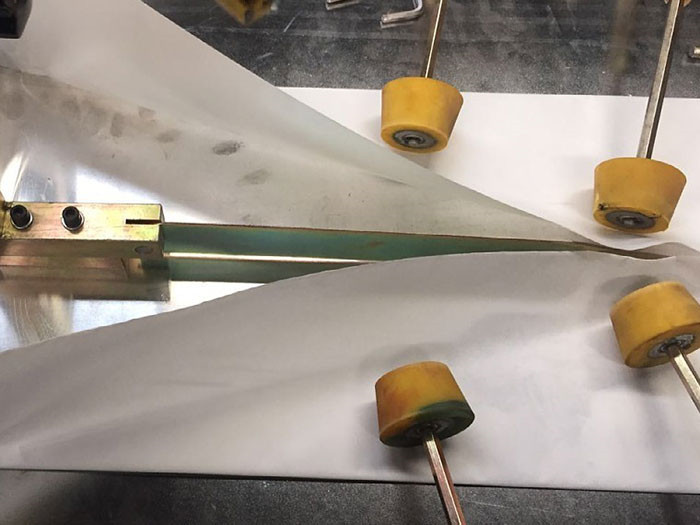

1.Rewinding device: Rewinding device uses magnetic powder, inflation shaft |

1. The main engine adopts frequency conversion speed regulation (1.5kw), and the frequency converter adoptsBlue |

|

2. Frame: Steel plate structure |

2. Servo motor (domestic) 1 for feeding |

|

3. Cross-cutting tool holder: castings structure |

4. Frequency Conversion Speed Regulation for Traction |

|

5. Using domestic common cutter |

4. Double Photoelectric Tracking and Positioning Device for Edge Rectifier (Zhejiang Julong) |

|

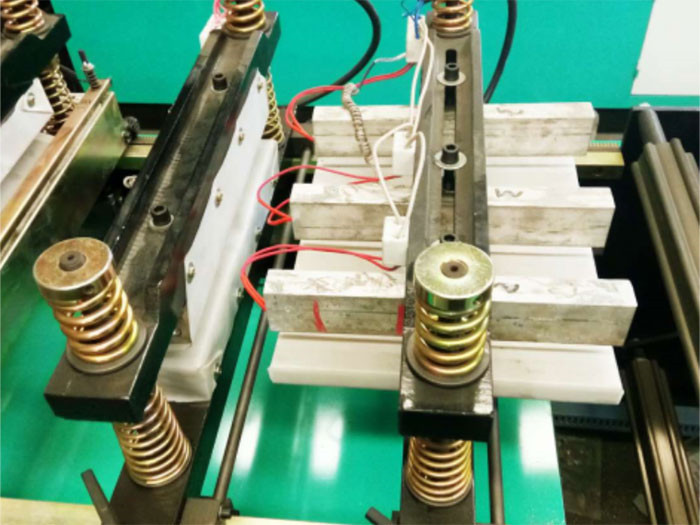

5. Driving axle: slotting with rubber axle 6. Blanking knife: The bottom cover is made of aluminium and visible structure (2 irons and 1 flats) Medium Seal Blanking Knife is made of copper parts |

5. Independent computer control cabinet: automatic counting, automatic alarm to the number. Automatic shutdown function |

|

7. Feeding traction mode: motor driven pulley driving traction rubber shaft |

Computer(touch screen) |

|

8. Maximum substrate width 700 MM, longest truncation length 350 MM |

7. The main engine adopts motor 1.5KW (Shanghai) |

|

9. Total weight 2000kg |

8. The fastest speed of the machine is 260/min (usually calculated by the length of the bag, such as 210 bags per minute, 200 mm long). |

|

10.machine size: length 5.2 m * width 1.4 m * height 1.5 m |

|