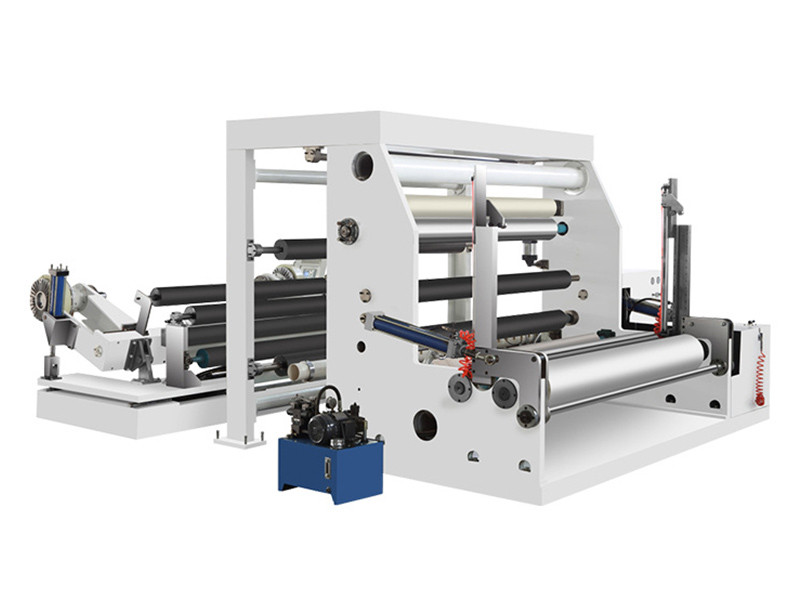

Aplicación: Esta máquina es adecuada para rebobinar y cortar papel kraft, papel estucado, telas no tejidas, etc.

Principales parámetros técnicos:

1. Ancho aplicable de la materia prima: 1300 mm

2. Diámetro máximo de desenrollado de la materia prima: carrete de φ1200 mm menos. Portabrocas mecánico de 3".

3. Diámetro máximo del bobinado de materia prima: φ1200 mm de ancho de corte: carrete tensor de 50-1600 mm, 3 pulgadas

4. Tensión de desenrollado: 400N. M x 2 juegos (freno neumático, válvula proporcional neumática SMC control automático de tensión constante)

5. Potencia del motor de bobinado: 16kw, convertidor de frecuencia correspondiente, bobinado de fricción de dos rodillos grandes.

6. Motor de soplado de bordes residuales: 1,1 kw

7. Velocidad mecánica: 300 m/min (velocidad de corte 5-300 m, regulación de velocidad de frecuencia variable)

8. Sistema de corte con cuchillas redondas, con 25 juegos de cuchillas redondas.

9. Tambor de bobinado: φ270 mm * 1750 mm, un rollo de acero (espejo cromado) y una barra de goma (material resistente al desgaste).

10. El marco está hecho de placa de acero de 50 mm.

11. Parte de control principal: tipo conectado aleatoriamente

Equipment configuration

Unwinding device

(1) Unwinding adopts hydraulic feeding. Shaftless cylinder clamping.

(2) Unwinding adopts pneumatic brake control, and PLC automatically calculates the coil diameter to realize constant tension control

(3) EPC correction device can accurately control the accuracy of the end face (driven by servo motor, with a maximum thrust of 5 tons), and the detection head is ultrasonic. The frame does not shake during the rectification. Correction accuracy±0.2MM。

(4) The unwinding diameter is the largestφ1200mm

2. Main frame: steel plate 50mm

3. Transmission structure: transmission mode: mainly using synchronous belt transmission

4. Guide roller: static balance aluminum alloy guide roller, surface hardening treatment. diameterφ120mm, roll surface width 1750mm.

5. Cutting device

The round cutter is used for cutting, and the rest is equipped with 25 pairs. The upper and lower axes of the round cutter are quenched and tempered without deformation. The slitting is stable.

6. Winding device

(1) The winding shaft adopts air expansion winding and is driven by a vector variable frequency motor.

(2) The winding form is friction type single winding with maximum diameterφ1200mm

(3) Pneumatic device is used to lift the pressure roller of the take-up shaft (the pressure is controlled by the precision pressure reducing valve)

7. Waste edge material blowing device: the fan suction device with power of 1.1KW is adopted (the edge material entering the air duct is equipped with a movable retaining ring device, which is suitable for cutting materials of different specifications and widths for trimming)

8. Automatic unloading device: complete the winding, and automatically unload the materials to the ground or cart by hydraulic lifting.

9. Control part

(1) Host control: PLC and touch screen human-machine interface are used for centralized operation of the whole machine.

(2) Unwinding part: automatic constant tension, automatic stop of broken material, automatic brake (prevent emergency stop in high speed operation, prevent inertia feeding)

(3) The winding part is controlled by full-automatic constant tension controller (PLC internal function), automatic metering, deceleration shutdown (metering basically without error), real-time linear speed display.

(4) Complete circuit diagram and operation manual are available

9. A set of tools shall be provided at random

|

No |

Name |

Model |

Quantity |

Brand |

|

1 |

PLC |

|

1 |

Siemens |

|

2 |

Motor |

16kw |

1 |

Guangdong hongyuan |

|

3 |

inverter |

16kw |

1 |

Shanghai dema

|

|

4 |

Ultrasonic probe |

Analog quantity |

/ |

Bianfu technology |

|

5 |

Rectifying thruster |

Servo motor |

1 |

Bianfu technology |

|

6 |

Corrective actuator |

|

1 |

Bianfu technology |

|

7 |

Pneumatic brake |

400N.M *2 sets |

2 |

china |

|

8 |

Pushing cylinder |

|

2

|

china |

|

9 |

Scrap fan |

1.1kw |

2 |

china |

|

10 |

Lifting cylinder |

Down rolling |

2 |

china |

|

11 |

Precision pressure regulating valve |

/ |

2 |

bailing |

|

12 |

Component |

/ |

/ |

Airtac |

|

13 |

Aluminum roller |

/ |

/ |

china |

|

14 |

Air shaft |

Rewind |

1 |

china |

|

15 |

Round knife |

/ |

/ |

china |