Aspectos destacados de la máquina:

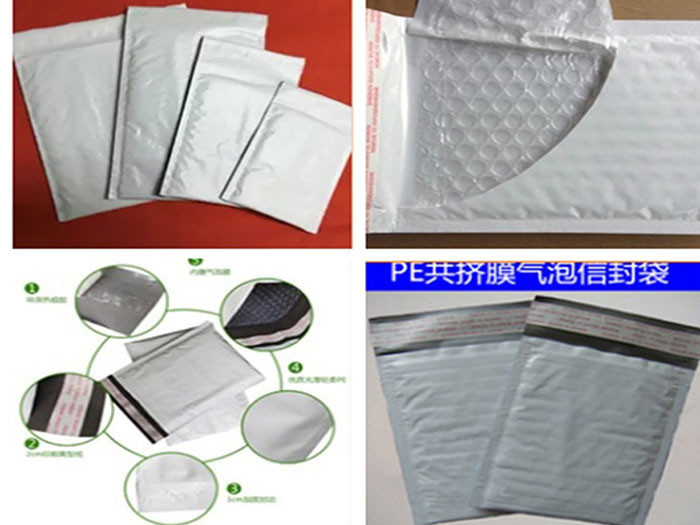

1. Esta máquina puede fabricar bolsas Kraft/poliéster/película perlada/aluminizadas y laminadas con burbujas.

2.La máquina puede fabricar bolsas en una línea o en líneas gemelas. Longitud de fabricación: 500 mm.

3.La máquina puede conectar la película de burbujas sin detenerse.

4.Esta máquina adopta el control de movimiento como sistema de control principal desarrollado en la empresa.

5.Sistema de seguimiento ocular fotoeléctrico doble que puede ajustar la tensión de la película al sellar para evitar que la película se estire al sellar de manera efectiva. Y el ojo eléctrico realiza un seguimiento independiente de los cortadores al realizar material impreso.

6. Esta máquina utiliza un servo doble “YASKAWA” para una longitud fija.

7. Marco de desenrollado de doble posición de trabajo de la máquina de pegamento termofusible.

8.Esta máquina está equipada con varios sistemas de control de desviación de película para controlar la parte plegable.

9. Esta máquina está equipada con una computadora independiente que rectifica la desviación en condiciones de desenrollado en una sola posición de trabajo.

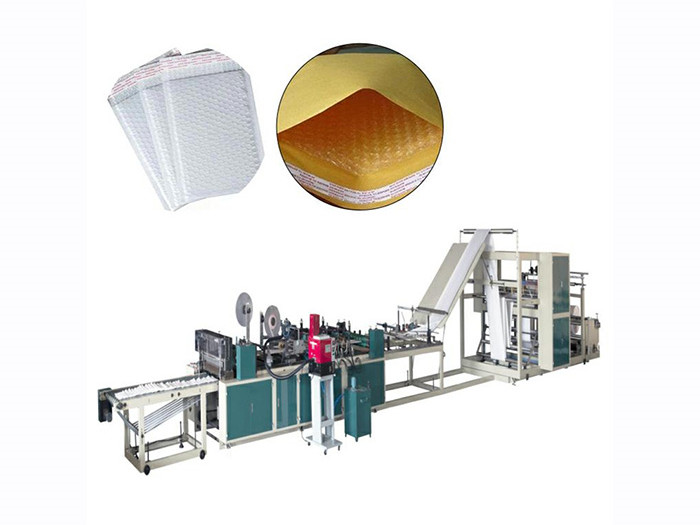

一、Introduction of machine

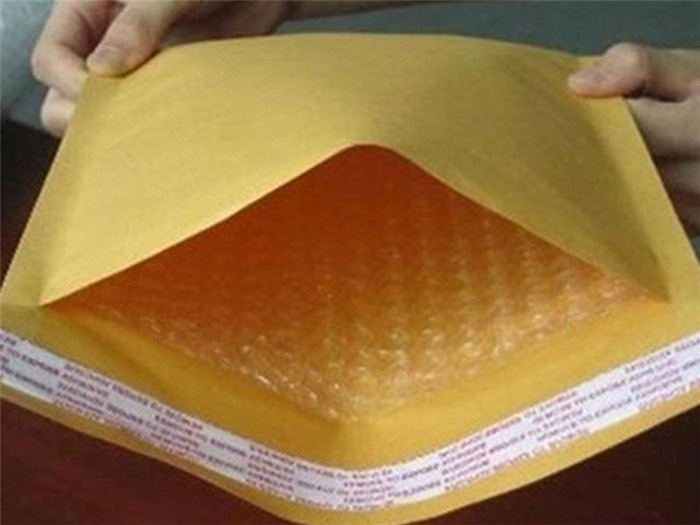

1.This machine is professional one to make bubble mailers from laminated bubble film.

2. The way of bag making: From laminated film to folding device, heat pressing, cross sealing and finally cut to standard laminated bubble mailers.

3. This machine uses advanced motion controller technology. It is controlled by computer program from film unwinding to cutting. This machine is a high-quality , easy-operational and professional one to make good-looking and durable bubble mailers.

二、Technical Parameters

1. Suitable material:

Polythene and bubble film roll

Aluminized and bubble film roll

Pearl film and bubble film roll

|

型号 Model |

NPPJ-800 |

NPPJ--1000 |

|

制袋长度 Max.Cutting Length |

100-600mm |

100-600mm |

|

制袋最大宽度 Max.Width of base material |

≤700mm(一出一包括信封舌头) ≤350mm(一出二包括信封舌头)

|

≤900mm(一出一包括信封舌头) ≤900mm(一出二包括信封舌头 |

|

制袋速度 Capacity |

40-100X2 PCS/MIN |

30-100X2 PCS/MIN |

|

有效放料宽度 |

≤1400MM |

≤1800MM |

|

放料直径 |

≤1000MM |

≤1000MM |

|

总功率 Total power |

35KW |

38KW |

|

机械重量(大概) Mechanical weight (approx.) |

4200KG |

4500KG |

|

制袋机械尺寸(大概) Bag making machine size (approximate) |

17200×2300×2500mm |

17200×2500×2500mm |

|

工作电压 |

380V50HZ 三相五线(三条火线,一条零线,一条接地线)

|

|

|

(Note:the actual speed of making bags may differ according to the size of bags, thickness of materials and time of fusing.) |

||

三、Main Configuration:

1. Computer control:

This motion control system.

10 inches touchable human machine interface, vertical and rotary type.

Two sets of 1.5 KW servo motor for fixed length.

Equipped with Germany high speed tracking electric eye.

The machine has functions such asauto-counting, alarming, stopping when a set of bags been made, and showing bag number, sealer and cutter stop at the highest position etc.

2. Cutter part

The machine is equipped with cold cutter of mechanical coordinatedtype, which check the colormark, and then the stepper motor moves the cutter front and rear to cut thematerials.This parthasPlexiglas protectors and posted with warning signs.

Equipped with on set of cold cutter.

3. Feeding Material Part

This part is for sending the laminated film to the folding pallet stably by the redundancy swing arms.

1. Idler roller for traction.

2. Press folding line by heated copper wheel.

3. Feed the material by redundancy swing arms make the tension equally in any position.

4.The machineUses vector inverter to control the speed And the feeding material motor is equipped with a decelerating box.

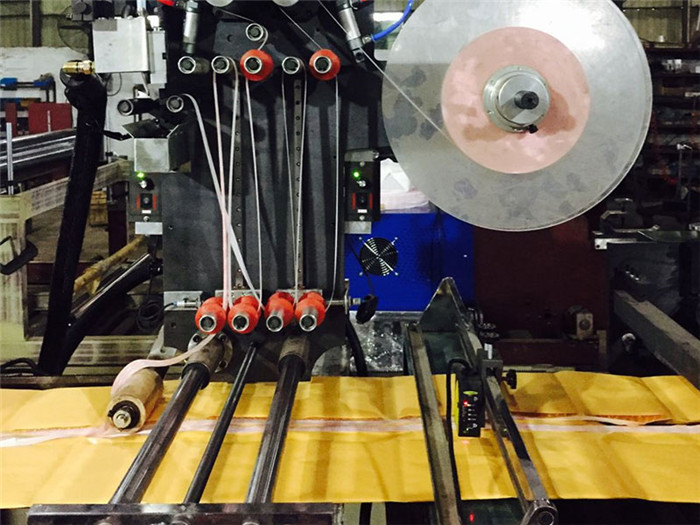

4. Hot glue part:

1. The maximum diameter of the release paper’sreel, release film’s reel and sticker adhesive reel :400mm

2. The diameter of rolling paper core:76.2mm

3. The machine is equipped with adhesive sticker unit with electric motor feeding. It can adhesive the sticker and material together when material moves.

4. The machine is equipped with a set of hot melt glue machine.

5. Transforming the glue on release film or release paper to compounded material by glue gun.

6. It has the function of incontinous glue spraying.

5.Sealing part

The main function of this part is to shape the laminated material by heat pressing and sealing.

The machine adopts high-power vector inverter for speed regulator, and the main motor with reducer.

Double servo motors to fixed length and pull the material.

Mechanical Pressing type shaping.

The width of hot sealing is 20mm 3 sets

Cold press shaping device 2 sets(including flat knife and serrated knife)

Needle bar 1 set

The surface of hot sealer is protected by“teflon”material.

6. Folding parts

1. Feeding the laminated material to fold position and then fold.

2. Duringfolding, there is a single-eye tracking correction system to make sure the tongue of envelopes are unanimous after folding.

3. Two sets of single roller folding devices when the machine is one-out-of-one style.

4. Integral-roller folding device when the machine is one-out-of-two style (the size of double-rollers providing bycustomers. And we assemble threepairs. If the company need other specificationdevice, they should place an additional order.

5. Pressing line and Feeding Material Part:

This part can feed laminated material automatically through the redundancy swing arms.

The machine adopts vector inverter as speed regulator and the feeding motor is equipped with a reduction gear box.

6. .Nonstop connecting film part

Flat table type non-stop connecting film device( connect the film by hand)

7. Bubble unwinding part

1.Maximum diameter of unwinding: 1300mm

2.Maximum width of unwinding:1400mm

3. Double work position cantilever type air shaft unwinding

4.Mechanical type tension control

5.Alarming device when materials run out.

6.Rectifying deviation system. This part adopts double electric eye tracking to make sure the machine run stably and the precision of deviation rectifying.

7.This part is also applicable to poly bubble film roll, aluminized bubble film roll, pearl bubble film roll etc.

10.transforming platform part

Transforming bybelt, which can transform the produced envelopes in order.

This parts is steel machine body.

四. Supporting facilities:(The buyer supply)

1.Power: 3-phase 4-wire AC380V 50Hz and ground earth (notes: The steel diameter must at 30-50mm, the length is more than 1.5m put into the ground, there is a line conductor which has 4 square mm at the upper) Forbid the null line connecting the machine.

2.Installation filed: In order to make the machine run well so that the buyer

must supply the good place to run machine.

3.Air pressure:

≥5kg/cm² constant pressure

35KW

4.Power required:

35KW