1、 Machine parameters:

PRODUCT:PE STRETCH FILM

PRODUCT WIDTH:100-1000mm/3*300mm/2*500mm

PRODUCT THICKNESS:0.012-0.05mm.

RAW MATERIAL:LLDPE

LAYER:A/B/A

RATIO:40%/60%

SPEED(max):120m/min

POWER:3P,380V,50HZ

WHOLE POWER:75KW

FILM ROLLER DIA:φ300(MAX)

PAPER CORE ROLLER: INNER φ 76* ,OUT φ 96mm.

DIMENSI(mm):L7000mm*W3000mm*H3400mm

二.SPECIFICATION:

1.SCREW BARREL(zhoushan make)

2.MAIN MOTOR 15KW & 22KW

3.MAIN INVERTER“DELTA”BRAND, 15KW &22KW

4.HEAT: ALUMINUM COATING HEA(ENERGE SAVING, DURABLE);

5.AUTO CHANGE ROLLER BY PLCAND WIND WITH EXPANSIVE ROLLER (EXPANSIVE ROLLERS 2PC IN TAIWAN BRAND)

6.PLC Mitsubishi

7.SUB EXTRUDER “RAIL TYPE MOTOR DRIVEN”

8. NEW ADVANCED SUB EXRUDER SWING

9.NEW HIGH SPEED STRUCTURE AND SWING PART

10.COVER ON MAIN BARREL MOVES FREE

11. BUFFER EQUIPMENT “SENSITIVE CYLINDER”

12.UP ROLLER “CYLINDER PUSH”

13.COOLING ROLLER φ420MM, WINDING ROLLERφ420MM(THE LAST ROLLER IN MIRROR TYPE)

14.TWO AUTO LOADER ,2PC

15.FILM EDGE COLLECTOR DEVICE, 1PC

16.TEMPERATURE CONTROL SYSTEM

17.SOLINEID

18.FILM EDING PINNING DEVICE, 1PC

三:SPECIFICATION IN DETAIL:

1.“A”EXTRUDER, 1 SET

(1)SCREW(zhoushan)

DIAMETER:φ55mm L/D RATIO 30:1

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT

(2)BARREL(zhoushan)

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT ON INNER AND OUTER PART.

HEAT: ALUNIMUN COAT HEAT

COOL: FAN COOL IN LOW NOISE

HEAT CAPACITY 12kw

(3)EXTRDER GEARBOX ZLYJ SERIES, WITH FORCED LUBRICATION

(4)MAIN INVERTER 15kw WITH MOTOR 15KW

2.“B”EXTRUDER, 1 SET

(1)SCREW(zhoushan)

DIAMETER:φ75mm L/D RATIO 30:1

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT

(2)BARREL(zhoushan)

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT ON INNER AND OUTER PART.

HEAT: ALUNINUM COAT HEAT

COOL: FAN COOL IN LOW NOISE

HEAT CAPACITY 15kw

(3)EXTRDER GEARBOX ZLYJ SERIES, WITH FORCED LUBRICATION

(4)MAIN INVERTER 22kw WITH MOTOR 22KW

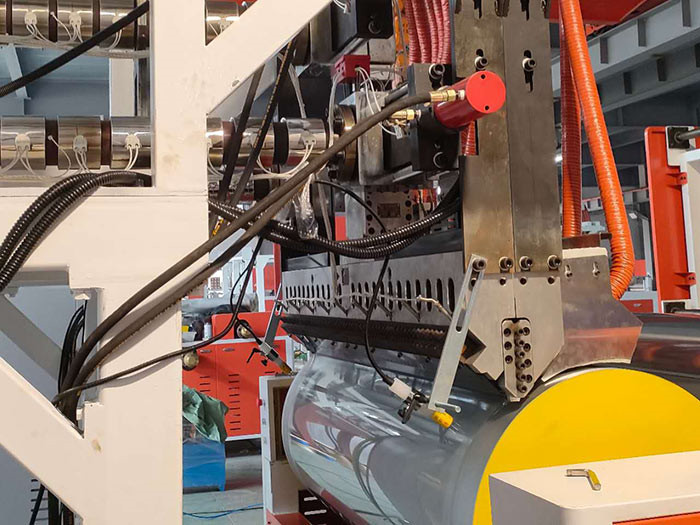

四、CO-EXTRUDER DISTRIBUTOR,1 PC

1、LAYER DISTRIBUTOR:A/B/A 3 LAYERS

2、HEATER:INNER HEAT WITH STAINLESS HEATER

3、HEAT CAPACITY:8KW,380V.

五、T DIE:

1.PRODUCER:taizhou huangyan

2.WIDTH:1250mm

3.MATERIAL:718

4.STRUCTURE:(INSERTING HEATING TUBE,TOTALLY ENCLOSED TYPE, AVIATION POLE SOCKET CONNECTOR)

5.HEAT CAPACITY:25kw

6.OVERALL CAPACITY:75kw

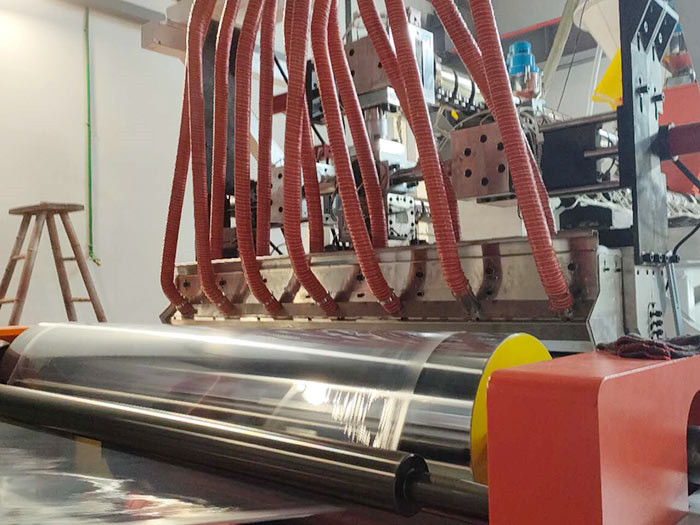

六、WINDER

1、CHILL AND SHAPE ROLLER 2PC

COOLING SYSTEM::SPIRAL FLOW , SUPER GRINDING, CHROME COATING, WATER COOLING

COOLING CYLINDER: DYNAMIC BALANCE OF ALL ROLLERS TO KEEP QUALITY OF FILM

2、TAKE UP AND WINDER ROLLER 2PC

(SUPER GRINDING AND CHROME COAT)

3、ALUNINUM ROLLER(TAKE UP ROLLER NO POWER IF OVERLOAD) 3PC

4、SPREAD ROLLER 2PC

(DYNAMIC BALANCE OF ALL ROLLERS TO KEEP THE QUALITY OF FILM)

5、PRESS ROLLER 2PC

6.SLICE ROLLER. 1PC

8.ROLLER CHANGE:AUTOMATIC PLC CONTROL, INVISIABLE SLICE

9.UP WINDING: UP CYLINDER AUTO WINDING DEVICE

10.WINDING:EXPANSIVE ROLLER WIND 2 PC

11. SUB EXTRUDER “RAIL TYPE MOTOR DRIVEN”

七、ELECTRICAL CONTROL PANEL

1、MAIN EXTRUDER/ INVERTER CONTROL, 1 PC

2、SUB- EXTRUDER/ INVERTER CONTROL, 1 PC