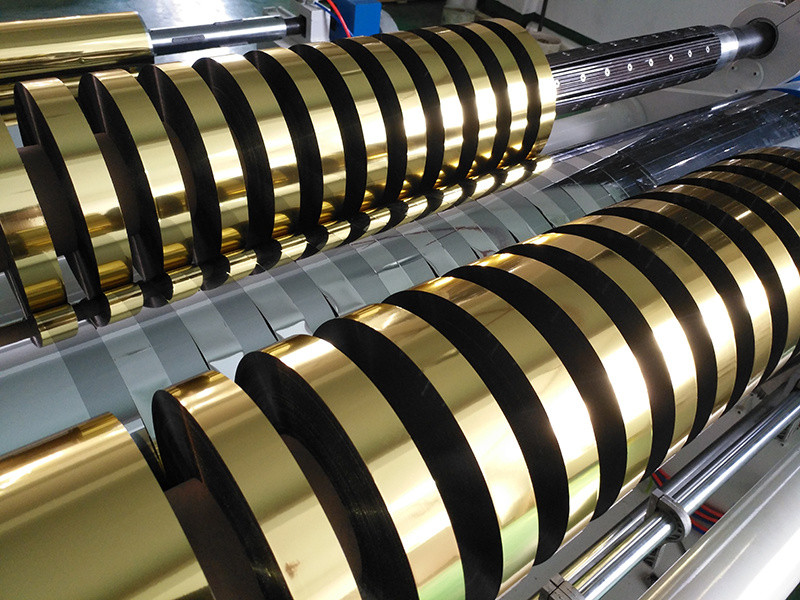

Aplicación: Esta máquina es adecuada para cortar todo tipo de telas no tejidas, telas fundidas por soplado, algodón con aire caliente y materiales de tambor.

Característica:

La máquina adopta control por computadora, sistema de rectificación y seguimiento fotoeléctrico por infrarrojos, y el control de la tensión del devanado se realiza mediante un embrague de partículas magnéticas a través de una pantalla táctil PLC. La tensión de desenrollado está controlada por un freno de partículas magnéticas y una tensión automática. El eje de bobinado adopta el eje de expansión de gas. El convertidor de frecuencia controla la velocidad de trabajo de toda la máquina, equipada con un dispositivo medidor automático, y ralentiza la máquina en cualquier ajuste del medidor. El diámetro mínimo de desenrollado se puede configurar para que se detenga automáticamente (para evitar el desperdicio causado por la alimentación secundaria). Tiene las ventajas de un corte suave, una cara final limpia del devanado y conveniente para el procesamiento posterior.

Separador de tiras de alta velocidad serie QFJ-C1600 para bobinado de superficie central

1、Main technical parameters

Maximum unwinding diameter:φ1000mm pneumatic roll up

Maximum winding diameter:φThe 650mm swing arm is unloaded, and the shaft is not unloaded, which is convenient for one person to operate.

Diameter of winding shaft: 3in

Diameter of winding shaft: 3in

Width of roller surface: 1650mm

Mechanical speed: < 150m/min

Maximum working width: 1600mm

Minimum strip width: 100mm

Correction accuracy:±0.1mm

Precision of cutting end face:±0.05MM

Power of main engine: 5.5kW * 1 set

50n.m2 magnetic powder clutch

Unwinding brake: 50n.m

Power of blower at waste blowing side: 0.75kw

Total power: 7KW

Overall dimension (length, width and height): to be determined (specific specifications shall be in accordance with factory standard)

2、Main components of the machine

The machine is composed of the rectification and unwinding mechanism, the cutting mechanism, the winding mechanism, the transmission mechanism and the electrical control.

3、Main configuration and specifications of each organization

(1)Unwinding mechanism

The mechanism is equipped with manual vertical and horizontal adjustment, which can eliminate the tension and wrinkle caused by thin thickness or non-circular paper core at both ends of raw materials.

The output torque is balanced by adopting high linear magnetic particle brake as the releasing tension actuator, which can reduce the tension fluctuation to the lowest state.

1. unwinding specification: the maximum width is 1600mm, the air rising shaft of unwinding is expanded, and the cylinder is fed automatically

2. paper pipe clamping mode: pneumatic expansion shaft clamping

Specification: 3 in 1 gas expansion shaft

1 gas gun

3. tension control: magnetic particle tension control.

Output control: 50n.m magnetic particle brake, controlled by PLC touch screen automatic tension, real-time winding calculation and display, can be set automatically stop after winding, to prevent the main coil from being discharged, and unable to receive material.

4. deviation correction execution: the photoelectric eye tracks the base material, U-shaped infrared analog detector, and the rack does not shake during the tracking process. The correction controller gives the signal and the synchronous motor performs.

Specification: 1 photoelectric eye

4 straight guide rails

One set of deviation correction mechanism

1 set of photoelectric eye fine adjustment

(2)Cutting mechanism

The mechanism adopts circular cutter to cut, the cut is neat and has a long life. The cutting up and down tool shaft is adjusted and tempered, and the speed of the upper and lower cutter shafts is matched by gears. The tool is cut by rotating the handwheel, and the automatic tool is achieved by continuing to rotate.

1. Tool shaft: one upper and lower axis

2. Locking device: it has a quick tool leaning device, which can lock the upper and lower tool shaft to avoid the cutting quality problems caused by the upper and lower knives being separated or moved.

Specification: 1 pair of rocker arm

One locking shaft

Matching gear 1 pair

Worm gear pair 1 pair

15 sets of round knives

3. waste collection: blower blowing away

Specification: 1 fan

1 air duct

4. Main wall panel: steel plate wall panel is used to effectively shock absorption, and it is advantageous to the high-speed and stable operation of the machine.

Specification: 30mm

5. guide roller: surface hard oxidation and polishing treatment.

Specifications:φone hundred×1650mm

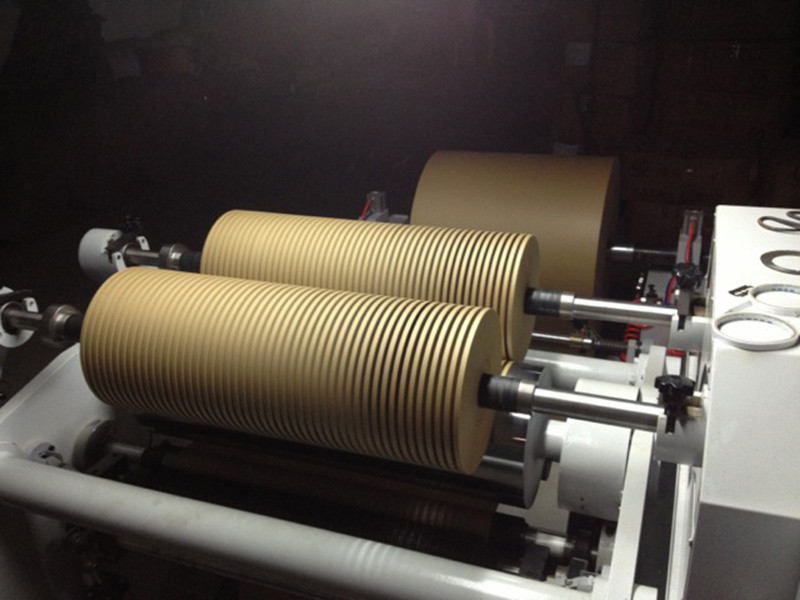

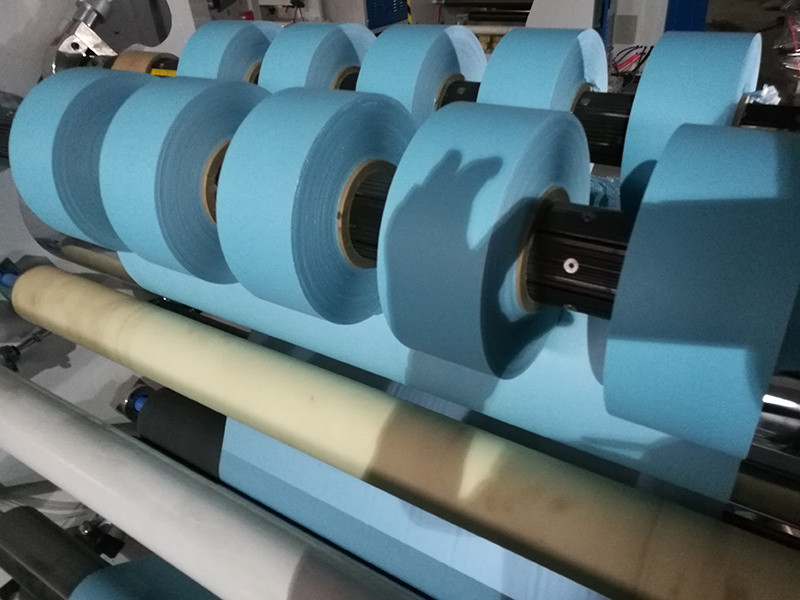

(3)Coiler

El mecanismo adopta un devanado de doble eje de eje izquierdo y derecho y está equipado con un brazo de presión para equilibrar la presión interna y externa del devanado. Se utilizan dos motores de polvo magnético para controlar la tensión del devanado, la tensión del eje único se puede ajustar arbitrariamente y la tensión se controla automáticamente.

Especificación del devanado: rango máximo 1600 mm, diámetro φ650 mm

Modo de sujeción del tubo de papel: sujeción del eje neumático (se puede determinar según las especificaciones de material del cliente)

Especificación: 6 piezas de eje de expansión de aire tipo mosaico 3 en 2

Presión del eje de bobinado: compresión neumática de presión diferencial, y la presión se puede ajustar arbitrariamente mediante una válvula reguladora de presión neumática

Especificación: 2 pares de brazos de presión

2 cilindros

Control de tensión: control automático de tensión a través de pantalla táctil PLC Siemens

Implementación del devanado: control PLC control automático de tensión del motor de partículas magnéticas

(4) Mecanismo de transmisión

El motor principal es controlado por el conductor, lo cual es conveniente y rápido para subir y bajar, y el ajuste de velocidad es demasiado suave y estable.

Modo de conducción: regulación general de conversión de frecuencia, accionamiento del motor de conversión de frecuencia

Especificación: motor de conversión de frecuencia de 5,5 kW

Convertidor de vector auxiliar (Delisi)

(5)Aparatos eléctricos principales: control centralizado de la caja del gabinete, hermoso y generoso, fácil de operar.

1 armario operativo

1 pantalla de medidor larga, realidad de velocidad de línea en tiempo real, función de parada automática del registro del medidor (con función de parada por desaceleración, básicamente no hay errores en el registro del medidor)

Un instrumento de control de corrección de desviación fotoeléctrica.

Botones, contactores, interruptores de aire, etc.

User self care:

1.50hz, 380V three-phase five wire power supply

2. foundation treatment

3. equipment for installation and raw materials and auxiliary materials for commissioning

List of main equipment configurations

|

No |

Name of Components |

Model of components |

Number |

Brand |

|

1. |

Rectifying device |

|

1 |

dongdeng |

|

2. |

Round and straight knife |

|

10 |

china |

|

3. |

Unwind powder brake |

100N.M |

1 |

shengda |

|

4. |

Hall sensor |

|

1 |

china |

|

5. |

Traction motor |

YS100A5P5 |

1 |

shanghai |

|

6. |

Roller clutch |

50N.M |

2 |

shengda |

|

7. |

Driver inverter |

HY series |

1 |

shanghai |

|

8. |

Trimming fan |

JH |

1 |

china |

|

9. |

Touch screen |

MT series |

1 |

Kunlun tongtai |

|

10. |

PLC and module |

XMZ series |

1 |

siemens |

|

11. |

Cylinder and solenoid valve |

|

1 |

AirTAC |

|

12. |

Cylinder |

CHD2F series |

2 |

china |

|

13. |

bearing |

|

1 |

china |

|

14. |

Rubber roller |

|

|

china |

|

15. |

Aluminum roller |

|

|

china |

FAQ

Q: How can we know the quality of your machine?

A: Customers can send material to us and then we use our machine to manufacture finished products which will be re-sent to customers.

Q: How to buy your machine?

A: Please send me inquiry to our email, when we reach a agreement, we will sign a contract to confirm our order.

Q: Are we still need to install the machine after we got?

A: We will adjust the machine before we deliver to you, also we will send you video and manual to teach you how to use the machine.

Q: Can I put my LOGO/brand on the machines and finish products?

A: Yes, Sure. Just send us your artwork.

Q: What about your warranty?

A: Our warranty is 1 years, all machine part can be replaced for free within 1year if broken(not including man-made)

Q: Is your company a factory or a trading company?

A: We are an integrated set of industry and trade company.

Q: Where is your factory? How can i visit your company?

A: Our factory is located in Ruian city,zhejiang province, China. Its about 40 minutes from shanghai by plane(4 hours by train). All our clients from home and abroad are warmly welcome to visit us.

Q: How many years of your factory?

A: Our company since 2000 till to now.