1. Objectif

Cette machine convient à la découpe et au rembobinage de divers types de matériaux de type tambour. Par exemple, la découpe et le rembobinage de divers types de papier 50-300g/m2 (papier en plaque de cuivre, papier double caoutchouc, papier couché, bourrage de papier blanc, etc.), de matériaux composites papier-plastique et d'autres matériaux de tambour.

2、Performances et caractéristiques

1. La machine adopte une commande synchrone d'asservissement à trois moteurs, une tension conique automatique et un mode d'enroulement de la surface centrale ;

2. La machine adopte une régulation de vitesse de conversion de fréquence pour maintenir l'accélération d'un fonctionnement fluide et stable ;

3. Compteur automatique, alarme et autres fonctions ;

4. L'enroulement adopte la structure de l'arbre de gonflage supérieur et inférieur a et B, et la chaîne se décharge automatiquement ;

5. Coupe au couteau circulaire

6. Structure d'alimentation hydraulique/pneumatique libre axiale ;

3、Paramètres techniques

1. Largeur de la machine : type 1600, largeur limite maximale du papier : 1600 mm

2. Épaisseur de coupe : 50g/㎡-300g/ M2

3. Diamètre maximum de déroulement des matières premières : φ1200mm

4. Diamètre maximum de l'enroulement du produit fini : φ1000mm

5. Largeur minimale de coupe du produit fini : 20 mm

6. Diamètre de l'arbre d'expansion d'air de l'enroulement : 3 po. Deux

7. Nombre d'arbres d'enroulement en même temps : 2

8. Précision de coupe : ±0,3 mm

9. Vitesse mécanique : 50-400m

10. Puissance totale : environ 26KW

11. Dimension extérieure : (longueur, largeur, hauteur) 3700 × trois mille quatre cent cinquante × 1900 mm

12. Poids : environ 4500 kg

13. Couleur du corps : blanc principal (personnalisable)

4、Machine configuration

1. unwinding part: automatic axial-free hydraulic feeding (maximum load-bearing capacity 1.3t)

(1) 3-6 "paper clamp for discharge

(2) The frame is made of steel plate, and the left and right movement adopts straight rail

(3) Tension control: magnetic particle control is adopted for tension, with 20kg of 2 sets

The driving guide roller is made of aluminum guide rod and is treated with surface treatment( φone hundred×1650mm) 3

(4) The material is made of 3-6-inch self-locking mechanical sleeve.

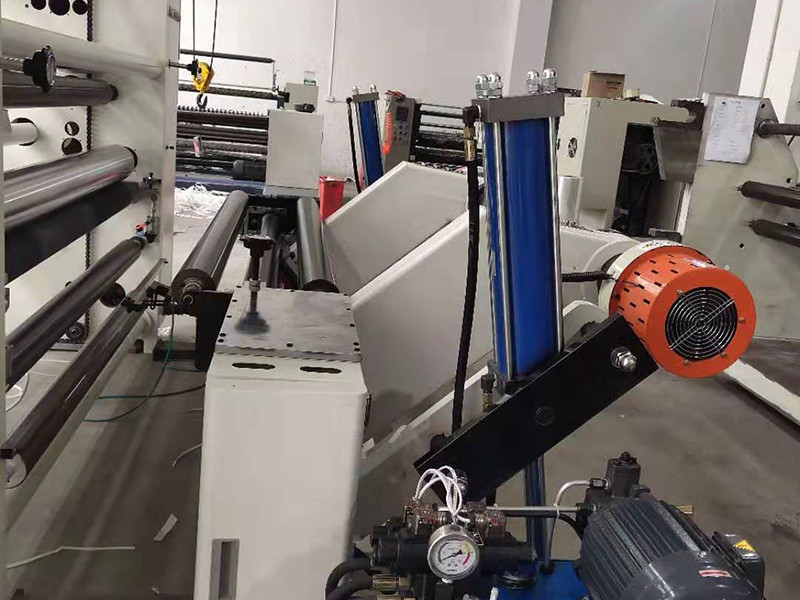

2. Main machine part: (adopting the up and down winding structure)

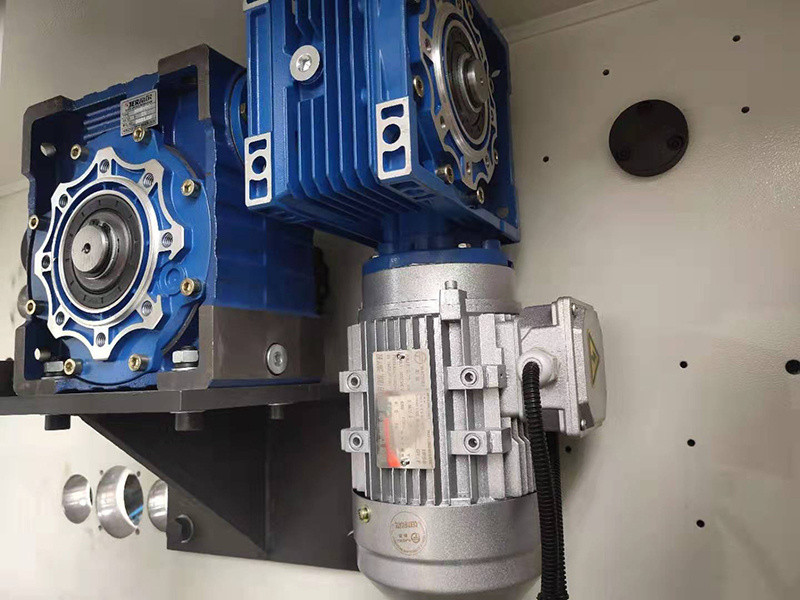

1) Drive and drive mechanism:

(1) The combination of motor and speed ratio of reducer is adopted actively

(2) The main motor is 7.5kW of Zhejiang dochuan servo motor

(3) The frequency converter adopts sine 7.5kW 1 set

(4) The transmission adopts the combination of synchronous wheel and synchronous belt, and the synchronous belt adopts imported brand

2) Traction device:

(1) Structure type: active traction pneumatic compression mode

(2) Driving mode: main motor drives main drive shaft, and main shaft drives driving driving roller to pull

(3) The compression mode is controlled by cylinder

3) Cutting device:

(1) Adopt the structure of the cutter cutting device

(2) The upper and lower round knives can be adjusted manually at any time for 7 payment

3. Winding device

Structure: adopt the structure of upper and lower double expansion shaft winding at the same time

(1) The manipulator adopts the linear guide rail operation mode

(2) Taiwan silver is used for straight track

(3) Key strip type air expansion shaft is adopted for winding shaft( φ3 "spec) 2

(4) The winding motor adopts the multichuan servo motor 7.5kw

(5) 2 sets of sine 7.5kW control (V6 model vector control) are adopted for the frequency converter

(6) Transmission mode: 2 sets of independent control mode of synchronous wheel drive

(7) Maximum winding diameter:φ1000mm

(8) All encoders are made in Japan under the brand of "Tokyo"

(9) Discharge motor adopts 1.5KW speed reducer with 60 ratio

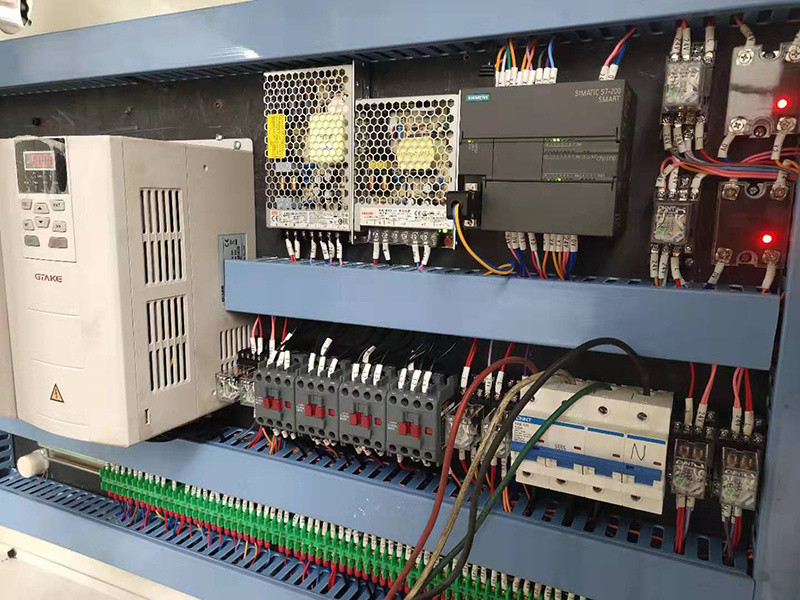

4. Control part:

Adopt one set of integrated control cabinet and distribution box for centralized control

(1) The control system of the machine can be divided into the speed control of the main machine, the tension control of the unwinding, the tension adjustment of the winding and the automatic meter, etc. are controlled by PLC. The touch screen adopts Kunlun Tongtai 7 inch, and the PLC adopts Siemens S7 system in Germany;

(2) PLC meter automatically; Alarm stop; Automatic length setting.

(3) Can be set cut length shutdown

(4) Schneider is used for switchgear

5. Supporting facilities: (the user is responsible for it)

(1) Power supply: three phase four wire air switch: voltage 380V 50Hz

(2) Air source: air compressor

(3) Toolbox

FAQ

Q: If we have very special request for the production line,could you help me to do the design?

A: Experienced mechanical designer customized-design provided.

Q: If we have samples of new products, can you help to analysis and design the machine?

A: Yes, Our technical department can help to analysis, design and test the new products you offered.

Q: Are you a factory or trading company?

A: We are a factory which license of import & export.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ruian City,Zhejiang province China. The nearest airport is Wenzhou airport(30mins driving). We would like to pick up you in that airport. Welcome to visit us!

Q: How long is the warranty period ?

A: ONE year.

Q: How about the installation? Do you have after-sale service?

A: We will send professional technician to your company to install the machine and train your staff until they could operate the machine independently.