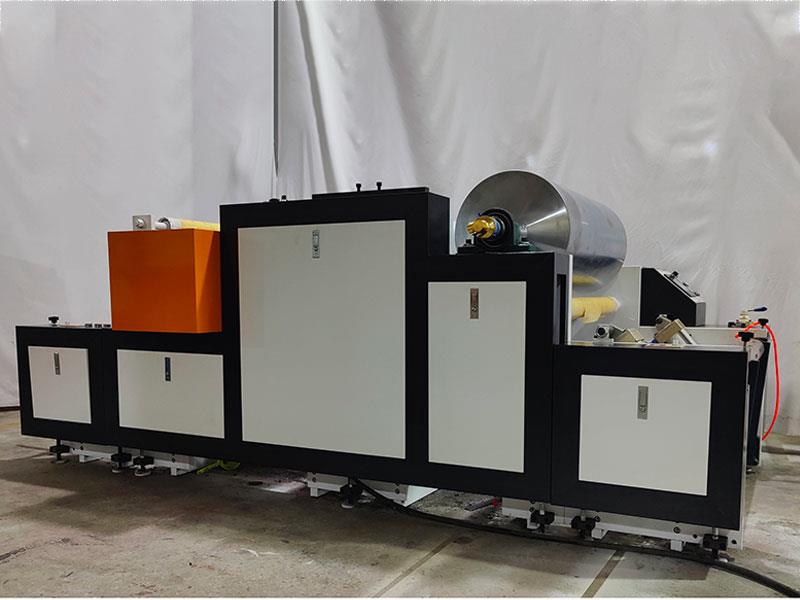

Configuration list

一. Unwinding unit:

1. First discharge: pneumatic loading rack simplex, maximum diameter 1200mm.

2. Second discharge: pneumatic feeding rack simplex, maximum diameter 1200mm, gantry type overfeed compound press roller.

3. Magnetic powder feeding: magnetic powder 10kg, maximum rotation 200N.m.

4. Discharge shaft: 1 set of 3-inch inflatable shaft.

二. Glue unit:

1. Roller transfer glue, scraper up and down before and after adjustable, gear motor swing

2. Pass glue structure, pass glue to the paper through the steel rod and roll

3. The glue is recycled by circulating pump.

4. Independent variable frequency motor drives the glue roller, and the glue roller synchronously and automatically switches the working state of the step by step control, so as to avoid the glue drying caused by the host stop during the step by step control

三. Embossing unit:

1. Pattern roller: 190×1150mm (1 piece) with heating function

2. Wool roller: 385×1150mm (1 piece)

3. Main motor: 5.5KW ordinary motor equipped with 1 to 11 reducer

4. Pressure: 2pcs for ¢80× ¢25 pressure cylinders in electro-hydraulic station (1 set),

5. Maximum pressure, 12MPa

6. Rotation: The chain rotates

四. Crosscutting unit:

1.Frequency conversion main motor 2.2KW (1 set)

2. Main motor with 1 set of reducer

3. Feed traction swing arm 2 sets with precision positioner control feed uniform speed operation, to ensure the stability of embossment unit

4. The cutter adopts CAM cycle linkage,

5. The fixed length feeding is controlled by touch screen computer, and the stepper motor drives the rubber roller to feed

6. Feed roller: aluminum guide roller brown dynamic balance

7. One set of round knife slitting device, with 3 sets of round knives

Main drive:

(1) Transmission mode: 1. Main motor traction

2. Chain rotation

3. Feed guide roller (aluminum roller, brown, dynamic parallel, hard oxidation) several diameter 80mm

(2). Subsidiary units:

1. Work protection device

2. Main wall plate steel plate, thickness 60mm

3. Chassis 120×80m square pipe, 15mm steel plate, welding, receiving and discharging rack 30mm steel plate finishing molding

4. Voltage: three-phase four-wire 380v, set for 50 or 60 Hz.

(3) The machine has PLC control, three motors synchronous, automatic tension magnetic powder discharge, to ensure the material smooth tension stability, uniform machine speed, clear pattern.

2. Main technical parameters

|

maximum diameter of uncoiling substrate |

1200mm |

|

inner diameter of the substrate core |

76mm |

|

Maximum width of embossing |

1050mm |

|

Embossing speed |

50m/min |

|

Tension setting range |

0-80N.m |

|

total power of the machine |

18kw |

|

machine weighs |

4500kg |

|

Paper range |

≥60g/㎡ |

|

Machine size (LxWxH) |

6800×1800×1650mm |