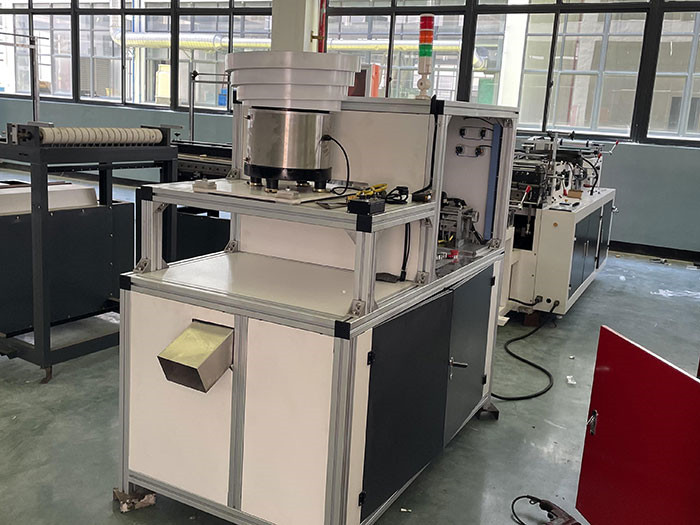

Performance characteristics:

The whole machine is controlled by microcomputer and dragged by stepping motor (optional servo motor control system). Any fixed length, step photoelectric tracking, accurate and stable, automatic shutdown in case of standard loss, and photoelectric control is adopted for feeding. It adopts horizontal triangle automatic folding, automatic winding and automatic labeling. Automatic meter counting and alarm can be designed. Automatic constant temperature makes the sealing firm and flat. The whole machine is convenient to use and saves labor. It is an ideal equipment in plastic flexible packaging machinery.

Basic parameters:

|

Model |

350 |

|

Product thickness |

0.01-0.015mm |

|

Product type |

Plastic film continuous roll bag |

|

Machine speed |

100—200(pcs/min) |

|

Bag length |

250-350(mm) |

|

Number of bag making rolls |

10(pcs/min) |

|

Small coil diameter |

25mm |

|

Small roll width |

60mm |

|

Motor power |

1.5(kw) |

|

Bag width |

180-235mm |

|

Host configuration: |

|

|

Frame structure |

10mm iron plate (optional channel steel body) |

|

Main motor |

1.5KW shanghai henglie |

|

Host frequency conversion |

1.5kw Dover |

|

Feeding motor |

Double stepping Songyang |

|

Discharging mode |

Simulated discharge |

|

Discharge motor |

0.55kw |

|

Discharge frequency conversion |

1.5kw |

|

Storage motor |

0.37kw |

|

Storage frequency conversion |

1.5kw Dover |

|

Temperature Controller |

Yuyao Keqiang xmt-9000 |

|

Reducer |

Hangzhou Jiahe 1:10 |

|

Electrostatic eliminator |

Ruian Hongwei 683 type output voltage 16Kv |

|

Electrostatic rod |

350mm×2 |

|

Tension |

Manual |

|

Harvesting method |

Heat sealing cold cutting |

|

Discharge shaft |

Mechanical shaft roller |

|

Feeding rubber roller |

5 pairs |

|

Rubber roller material |

polyurethane |

|

Feeding mode |

Pneumatic feeding |

|

Hot knife |

300mm copper knife fine brass |

|

Cold knife |

300mm MAANSHAN alloy steel |

|

Host size |

3700x1000x1200mm |