Application:

This machine is suitable for transverse cutting of pearl cotton, no harm cloth, gold and silver cardboard, A4 paper, plain rainbow paper, positioning laser transfer paper, whiteboard, plastic sheet, etc. The electrical main control system adopts computer step control or (servo system control), man-machine interface operation and dynamic display; The fixed length control is controlled by the private clothing motor system, and the photoelectric switch for automatic identification of the standard ensures the cutting accuracy. The control mode of the whole machine is advanced. The speed of the main machine, the imported stepping motor and the feeding motor are controlled by the computer to achieve synchronous operation. It has the advantages of high cutting precision, fast speed, convenient feeding and neat stacking.

Characteristic:

Compact structure, high degree of automation, with computer control, frequency control, automatic counting, sound and light alarm, photoelectric tracking and other functions. It is suitable for the transverse cutting of the web material after printing composite material, and is the necessary equipment for the web printing composite material cutting into pieces.

Main configuration:

1. Main motor: AC motor (1 set): (made by China Kangda) 1.5kw

2. Feeding motor: stepper motor 350A

3. Inverter: China Dover 1.5kw

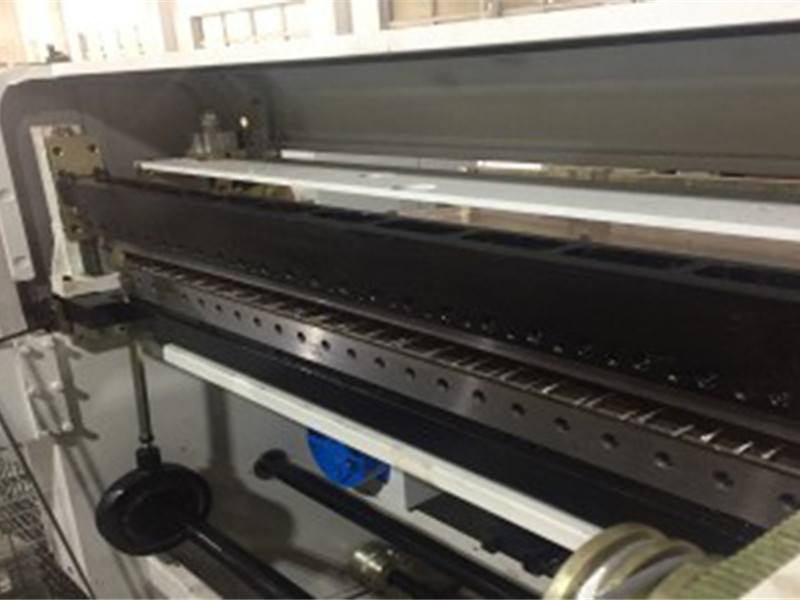

4. Cutting mode: cold cutting

5. Knife: one set (China MAANSHAN alloy steel aiii7)

6. Low voltage apparatus: (one set): (Chint)

7. Aluminum guide roller((Zhejiang)

8. Computer system (PLC) programming

9. Cots: (self produced) J hardened 2 (80 large) wear resistant

10. Switch: (Chint)

11. Electrical control box (self produced)

12. Main frame (self produced)

13. Voltage 220 V

14. Machine structure: channel steel No.8

15. A set of photoelectric tracking

16. 5 kg magnetic powder gas expansion shaft is used for discharging

17. A set of edge correction system

Description:

Jumbo Roll To Sheet A3 A4 A5 Paper Sheeting Machine A4 Making Machine In Stock shortens cutting and packing time, increasing productivity greatly and high accurate cutting.

|

Gross width |

1100mm |

|

Net width |

1100mm |

|

Number of cutting |

4cuttings-A4 210mm(width) |

|

Diameter of paper roll |

400-1200mm |

|

Diameter of paper roll’s core |

3”(76.2mm)-6”(152.4mm) |

|

Weight of paper sheet |

60-100gsm |

|

Length of paper cutting |

A4(297mm) |

|

Paper quantity |

0-500pages |

|

Ream height |

65mm(Max) |

|

Designing speed of paper cutting |

160m/min |

|

Times of cutting |

538/min |

|

Cycle time of ream exhausted |

4.3/min |

|

Real speed of paper cutting |

130m/min |

|

Times of cutting |

437/min |

|

Cycle time of ream exhausted |

3.5/min(14 reams/min) |

|

Load of paper cutting |

(max)400gsm(4×100gsm) |

|

Paper cutting accuracy |

±0.2mm(Permissible error) |

|

Paper cutting condition |

1.Speed not change

2.Paper roll with no breakage |

|

Transmission |

AC Frequency conversion,stepless speed regulating |

|

Main power source |

3phase/380v/50Hz |

|

Adjustable voltage |

220V AC/22V DC |

|

Installed capacity |

35KW |

|

Air consumption |

300NL/min |

|

Pneumatic pressure |

6bar |

|

Overall dimension(cutting machine) |

15000×2750×2100mm |

|

Weight |

12 T |

|

Overall dimension(packing machine) |

6000×3400×1600mm |

|

Weight |

2.5 T |

Features and Structure:

1) Non-shaft paper rising shelves of the ground controlling system------ Two sets

2) Advanced tension controlling system ------ Four sets.

3) Four sets of anti-warping mechanisms------Four sets.

4) Longitudinal cutting knife groups------Five sets.

5) Simultaneous cross-cutting knife group-----One set.

6) High-speed paper feeding system-----Three sets.

7) Low-speed paper feeding system-----Two sets

8) Waste paper automatically discharging system-----One set.

9) Making papers in order of 2D oscillation, the cylinder lifting device of reams of paper collecting system------One set.

10) PLC reams of paper counting device------One set.

11) Reams of paper longitudinally discharging equipment-----One set.

12) PLC failure alarm and machine haulting system and PLC controlling equipment ------One set.

Main Features:

1) This is a high level machine, which is designed for paper cutting, cigarettes package industry.

2) The main electric control system adopts center computer control (PLC), man-machine interface operation with dynamic display.

3) Constant length servo driving system is imported from Japan and photoelectric switch is imported from German to ensure cutting accuracy.

4) Unwinding tension adopts tension system of France KORTIS to ensure constant tension.

5) The material of blade is imported from German, with long service life.

6) Paper corner adjusting adopts advanced technology to ensure the accuracy of right-angle degree.

7) Feeding adopts stepless speed regulation to ensure single sheet feeding and overlapping sheet feeding smooth.

8) Collecting adopts automatic sort out material and automatic counting and inserting label so as to ensure heaping in order and counting exactly.

9) This machine is suitable for cutting printed roll material of chrome paper, gold and silver card paper, aluminium foil, laser paper, etc.

FAQ

Q: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More important, we put a high value on our reputation. High quality is our principle all the time. You can be assured on our production completely.

Q: How long does the whole procedure being worked out?

A: After you place an order,for small quantity 15-20 days is enough,for big quantity,we can talk further.

Q: How to buy your machine?

A: Please send me inquiry to our email, when we reach a agreement, we will sign a contract to confirm our order.

Q: Are we still need to install the machine after we got?

A: We will adjust the machine before we deliver to you, also we will send you video and manual to teach you how to use the machine.

Q: Is your company a factory or a trading company?

A: We are an integrated set of industry and trade company.