1、Application:

The machine is suitable for cutting all kinds of beverage packaging, mineral water standard cover, wine standard bottle cover, candy packaging, self-adhesive, paper, etc.

2、Performance and characteristics:

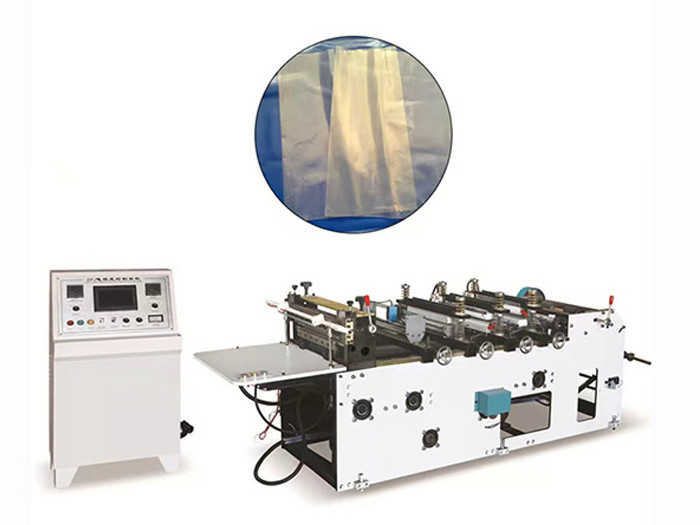

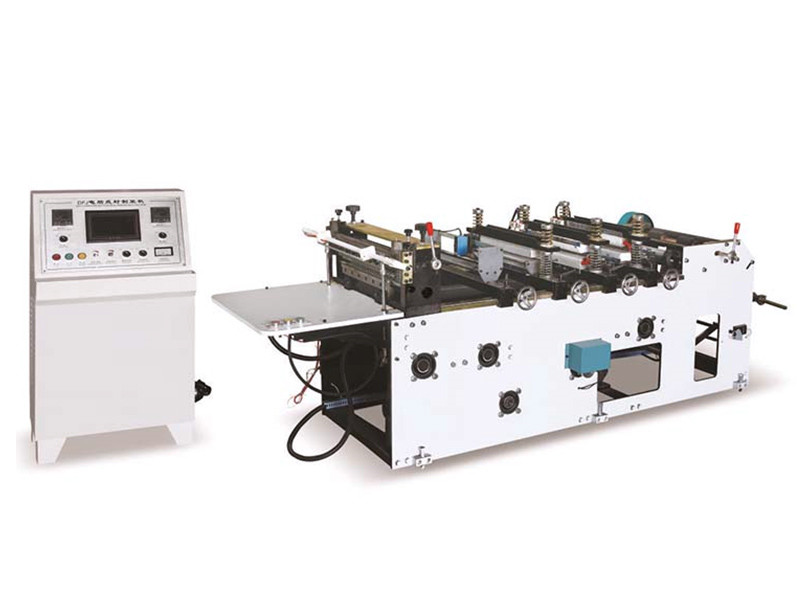

Zd-dfj series bottom sealing machine (also called sealing shear machine) is suitable for automatic bottom sealing and cutting of flexible packaging compound bags. The machine adopts microcomputer automatic control, frequency conversion speed regulation, photoelectric tracking, work counting, automatic temperature control, high position parking, two ironing and one cold sealing device, firm sealing and smooth sealing technology(According to the user's requirements, we can increase the die and tear, single film bag sealing and cutting device).

3、Set configuration

|

Mechanical part |

Electrical part |

|

1. unwinding device: the winding shaft is fixed by manual lock with cone sleeve |

1. The host adopts frequency conversion speed regulation (1.5KW), and the frequency converter adopts Hualan |

|

2. frame: adopt the steel plate structure of 10 mm |

2. step motor (Wuxi Songyang) is used for feeding |

|

3. cross cutting cutter base: casting structure is adopted |

3. 400W DC motor (Wuxi) is adopted for traction |

|

4. cross cutting knife: adopt domestic common cutter |

4. photoelectric tracking and positioning device (Zhejiang Julong) |

|

5. drive shaft: slotted with rubber shaft 6. ironing knife: copper knife (2 two ironing knives 10mm, 1 cold press) |

5. independent microcomputer control cabinet: automatic counting and automatic alarm when reaching the number. Automatic stop function |

|

7. feeding traction mode: motor drives belt pulley to drive traction rubber shaft |

6. main motor 1.5kw (machine voltage: 220V) |

|

|

7. computer touch screen (Wuxi) |