Overview, name, model, quantity and price:

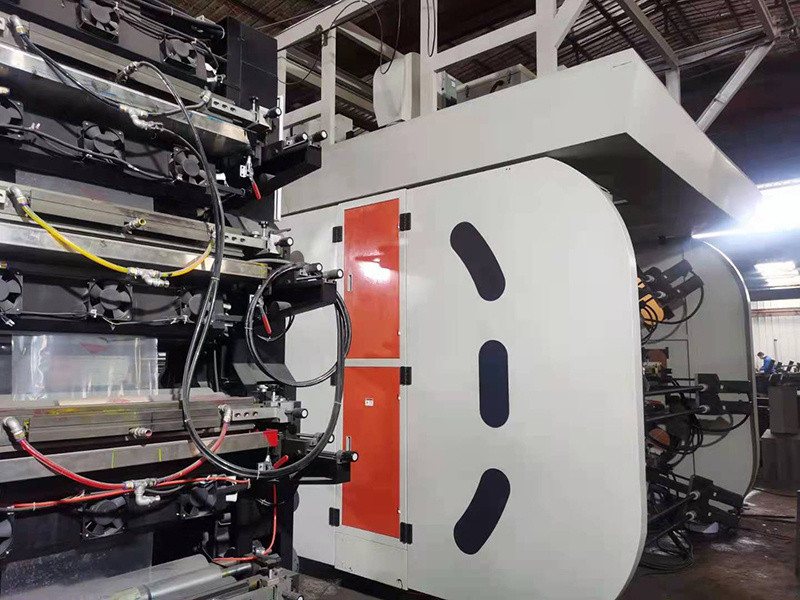

Satellite flexographic printing machine is a world advanced laminated flexographic printing and packaging equipment independently developed by our company on the basis of referring to foreign advanced technology. The machine is suitable for printing various materials such as woven cloth, self-adhesive paper, coated paper, aluminum foil paper, cardboard and plastic film. It is used with non-toxic and pollution-free water-based ink and has reached the environmental protection printing standard. Therefore, it is especially suitable for printing on food and drug packaging.

Main features:

1. Process flow: 1. Unwinding 2. Deviation correction 3. Unwinding traction 4. Flexographic printing 5. Receiving traction 6. Rewinding.

2. The maximum width of raw materials is 1000mm.

3. Maximum printing width: 960mm.

4. Printing method: satellite type.

5. Chromaticity accuracy: printing chromaticity accuracy:±0.15mm.

6. Maximum mechanical speed: 170m / min

7. Tension range: 2-10kg

8. Width of guide roller: 1030 mm

9.Unwinding diameter: maximumΦ1000 mm。

10. Winding diameter: maximumΦ1000 mm。

11.Overall power (about): 81kw.

12. Heating mode: electric heating 63kw.

13. Overall dimension (about): length 7.5×Width 2.75×3.6m high

14. Body color: the main body color is silver white, and the transmission shield and safety shield are orange.

15. Total weight of fuselage (about): 11 tons.

三. Main configuration

1. Unwinding unit (magnetic particle automatic tension control) : 1 set

2. feeding traction unit: 1 set

3. Flexographic printing unit 6 colors

4. material receiving traction unit: 1 set

5.Slitting: 1 knife

6.winding unit: 1 set

四 . Main configuration details:

1. Unwinding unit (magnetic powder automatic tension control)

1) Structure: single station unwinding.

2) Left and right adjustment of base material: automatic edge correction adjustment±50mm.

3) Maximum diameter of unwinding:Φ1000 mm。

4) Tension control: passive discharging, 10kg magnetic powder automatically controls the tension.

5) Installation method of paper core: 3-inch air expansion shaft.

6) Fixing method of expansion shaft: secure and fix with safety locking pin.

7) Discharging structure: swing arm type automatic loading and unloading device.

2. Feeding traction unit:

(1) Cots:Φone hundred×1030mm。

(2) Structural form: two axle phase pressure type, direct compression and active traction of large drum.

(3) Rubber roller pressing mode: air cylinder pressing.

3. Flexographic printing unit:

1) Printing method: flexographic printing.

2) Anilox roller: high precision integral ceramic anilox roller.

3) Ink scraping mode: cooperate with closed scraper to scrape ink evenly.

4) Ink supply mode: double diaphragm pump automatically circulates ink supply.

5) Feeding mode: the feeding of plate roller and anilox roller is pneumatic plus manual feeding.

6) Printing plate cylinder: integral printing plate roller.

a) Printing perimeter range: 300 ~ 1000mm.

b) Transmission mode: mechanical transmission

c) Longitudinal chromatic actuator: adjusted by reducer, accurate±0.15mm.

d) Horizontal color registration: speed reducer adjustment, accurate±0.15mm.

7) Ink supply system: Taiwan double diaphragm pump automatic circulation ink supply system to maintain the stability of ink color.

8) Drying system: each soft printing color group is equipped with a small oven, a large oven on the top, and the temperature is automatically controlled.

4. Receiving traction unit:

1) Structural form: two axle phase compression type, active traction.

2) Traction roller:Φone hundred and ninety-nine point zero four×1030mm, hard chrome plated on the surface.

3) Rubber press roll:Φone hundred×1030mm。

4) Rubber roller pressing mode: air cylinder pressing.

5. Winding unit:

1) Structure: single station winding.

2) Maximum winding diameter:Φ1000 mm。

3) Tension control system: detected by precision potentiometer, single drum friction receiving, and high-precision frequency converter automatically controls the motor.

4) Tension setting: it is adjusted by the precision pressure regulating valve, and the winding is active, and the tension is stable.

5) Installation method of paper core: 3-inch air expansion shaft.

6) Fixing method of air expansion shaft: the cylinder locking pin is locked and fixed.

7) Winding pressure roller: swing arm type pneumatic pressure roller, with automatic blanking of air cylinder.

6、Guide roller and standard parts:

1) Guide roller:Φ80 aluminum alloy guide wheel is subject to hard oxidation, dynamic balance and static balance treatment.

2) Transmission parts and guide roller bearings: imported.

3) Main pneumatic control components: domestic.

6. The whole machine control system: it is controlled by the central controller, centralized touch screen and PLC computer. The man-machine interface sets the process parameters, and displays the tension state of each section in real time to monitor the working condition. The main electrical appliances are Omron and Schneider.

7. Still image viewer: cosai still image.

五、Supporting facilities (prepared by users)

1. Power supply: three-phase five wire system, 380V, 50Hz.

2. Purification workshop.

3. Air source: pressure: 6-7kg / cm2.

The company reserves the right to modify the technical parameters of the machine without notice.