Technical parameters:

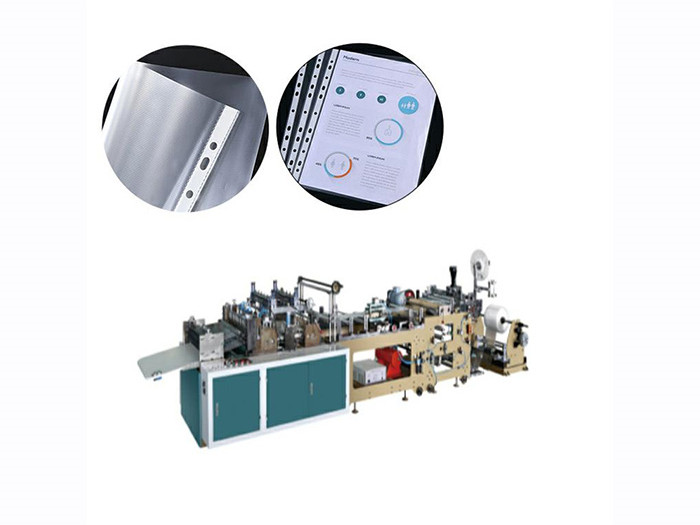

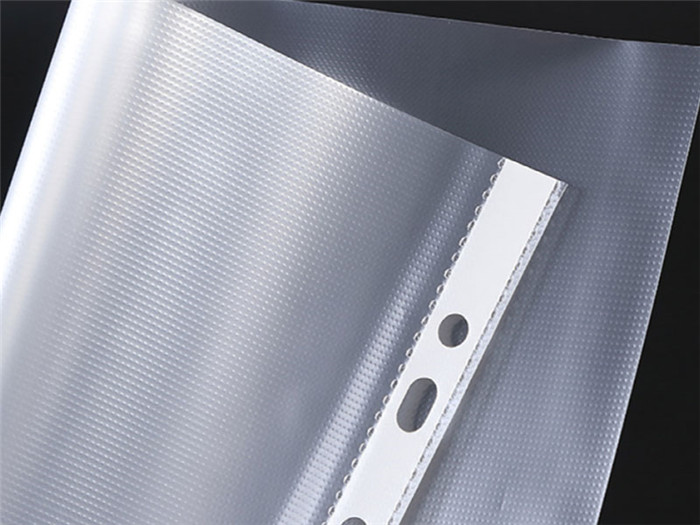

1. Scope of application: professional production of PP11 hole inner page and PP data book inner page.

2. Mechanical speed: 60 ~ 110 times / min.

3. Base material width: max. 500mm

4. Bag making length: 300mm ~ 500mm

5. Base material type: PP barrel

6. Effective sealing and cutting thickness: 0.025 ~ 0.06mm

7. Overall power: 7.5kw

8. Mechanical weight: 2.5t

9. Overall dimension: 6500x1500x2100 (L) × W × H mm)

10. Working voltage: three-phase four wire AC 380V 50Hz

II Main equipment configuration:

1. Fixed length control: servo motor and driver, PLC programmable controller and touch screen are used as man-machine operation interface.

2. Host: domestic frequency converter is adopted for host speed regulation control.

3. Feeding control: domestic variable frequency pneumatic swing arm feeding is adopted.

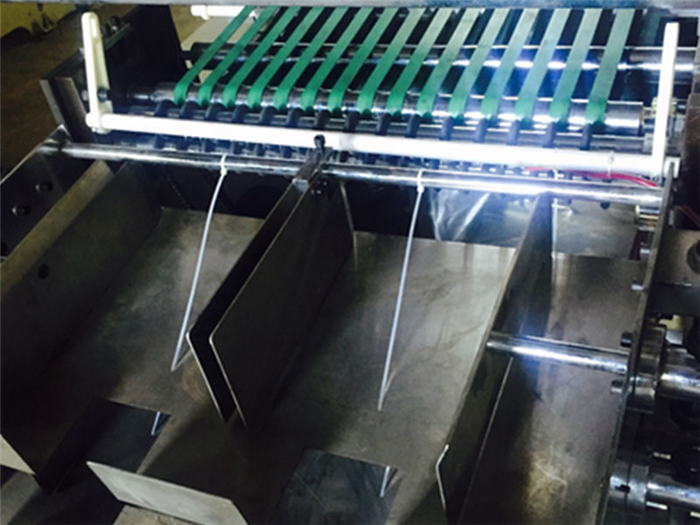

4. Ultrasonic knurling: domestic ultrasonic knurling is adopted.

5. Discharging deviation correction: double photoelectric deviation correction and magnetic particle tension control.

6. Knife sealing: external heating point knife sealing is adopted, and the temperature control is controlled by domestic famous brand temperature controller.

7. Equipped with 11 hole pneumatic punching die.

8. Equipped with a set of white strip lining device.

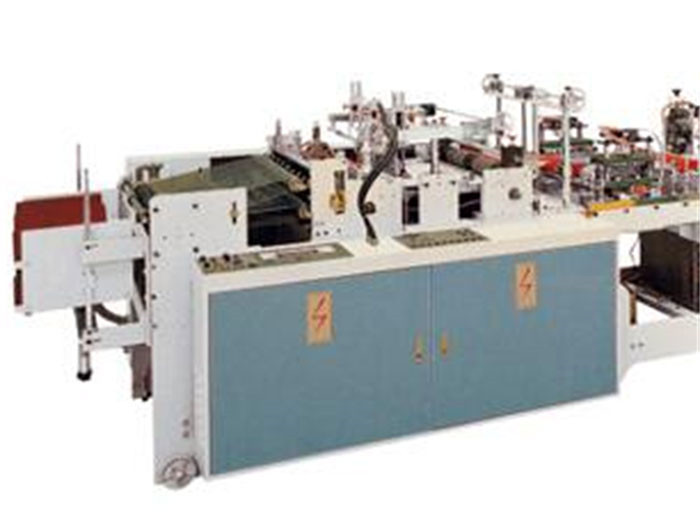

Zld-500a servo motor computerized data bag sealing and cutting machine

9. One set of barrel material opening device.

10. One simple receiving table.

III Supporting facilities: (please be responsible by the user)

1. Power supply: three-phase four wire AC 380V 50Hz and grounding wire. (requirements for grounding wire: the reinforcement or steel pipe with a diameter of 30-50mm and a length of more than 1.5m shall be directly driven into the ground and led out at the upper end with a conductor of 4.0 mm2). It is absolutely prohibited to connect the zero wire to the machine.

2. Installation site: the ground hardness is required to ensure that after the installation and commissioning of the equipment, there will be no foundation settlement during operation, which will make the equipment operate abnormally or damage the equipment.

3. Air source: pressure 5-10kg / cm ²

4. Standby power of the whole machine: 7.5kw