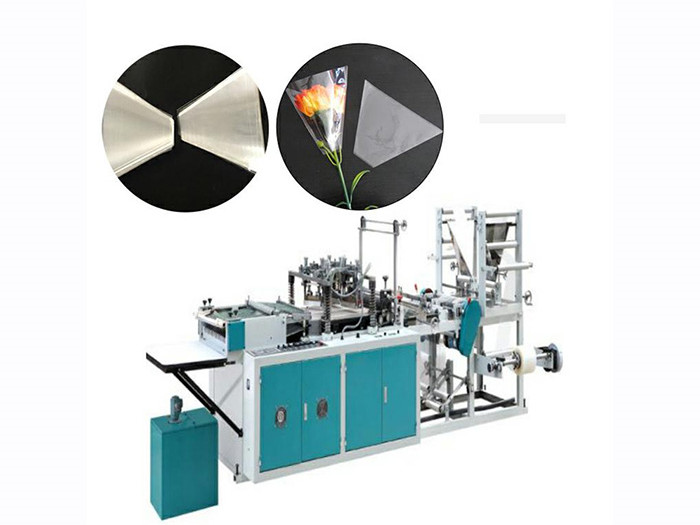

Suitable material: BOPP process flow: double side sheet loading - double side folding break - bag making.

Main technical parameters of equipment:

|

Maximum bag length (L) |

≤ 200mm or customized |

Length error |

±2mm |

|

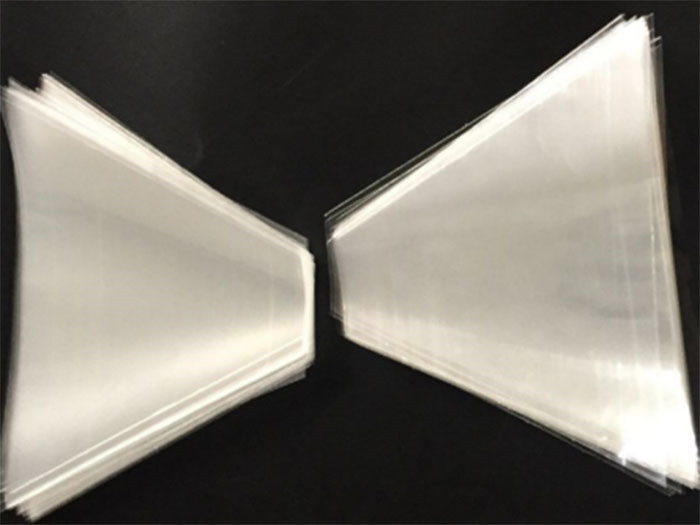

Small opening width (a) |

25-30mm |

Bag making thickness |

0.015~0.08mm |

|

Width of large opening (W) |

130-145mm |

Electrothermal |

2KW |

|

Speed |

30-120 times / min *2 |

Full standby power |

4KW |

|

Total weight |

900kg |

Power Supply |

220V/50HZ |

|

Overall dimension |

4200x1600x1400 |

|

|

Equipment electrical configuration:

|

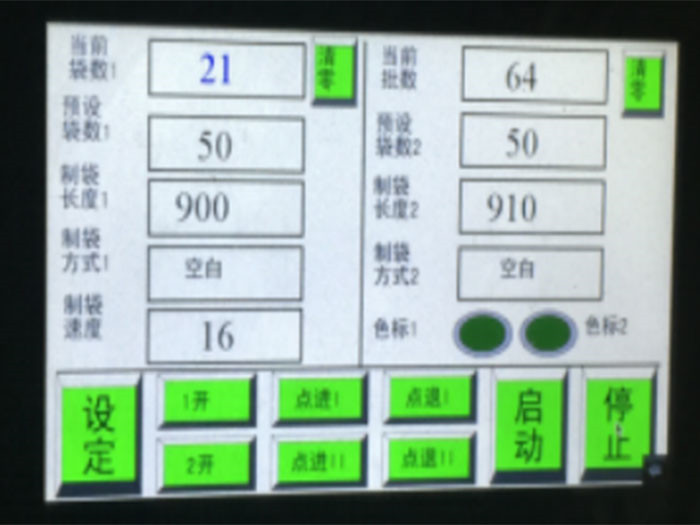

Control system |

Taiwan touch screen + Panasonic PLC programming |

Hot cutting tool |

2 sets of external heating flat knives, including cooling plates |

|

Main feeding motor |

350 stepper motor × 2 sets |

Discharge system |

Double line triangle half break |

|

Main motor |

Three phase motor |

|

Mechanical shaft discharging, 2.5kg magnetic powder manual tension |

|

Bag pulling motor |

1pc 0.55kw three-phase variable frequency motor |

Water cooling system |

Single phase water pump + water tank |

|

Feeding motor |

2pcs0.55kw three-phase variable frequency motors |

Tracking electric eye |

Longyou domestic electric eye 1pc |

|

Frequency converter |

1pc for1.5KW frequency converter 3pcs for0.75KW frequency converters |

Electrostatic device |

One set at the front and one set at the back |

|

|

|

Silica gel plate |

1650*530*5.5mm |