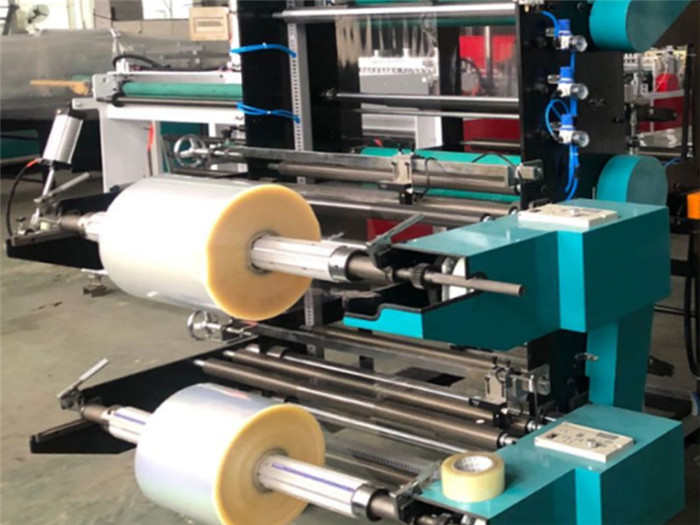

Trial materials: BOPP, CPP, LDPE, HDPE, POF, composite membrane and other materials.

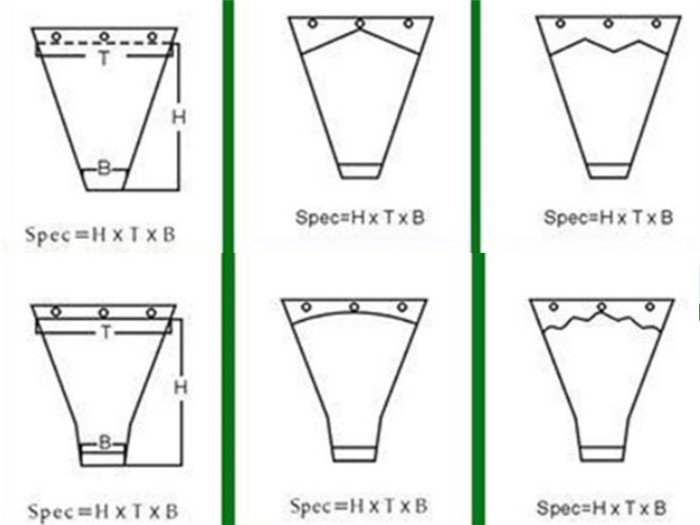

Application: Production equipment for flower bags, tower line bags, umbrella bags, sandwich bags, tie bags, triangular bags, trapezoidal bags and other special-shaped bags.

1. Touch operation, Panasonic PLC control, with photoelectric tracking, fixed length setting, automatic counting, automatic shutdown when material is broken, out of step alarm, high-level shutdown and other functions

2. Imported double servo motor drive

3. 5 sets of imported frequency converter + imported three-phase motor are adopted

4. Imported photoelectric switch is used for printing bag tracking,

5. Double deviation correction and discharging rack is adopted: inflatable shaft threading, magnetic powder total tension + automatic constant tension control, photoelectric deviation correction or analog deviation correction, stable and accurate discharging

6. It can be equipped with pneumatic drilling device, bottom ironing device, y-knife device, water cooling device and dotted line breaking device.

7. It is driven by 3M imported silicone plate.

|

参数 Parameter |

型号-600 |

型号700 |

型号-800 |

|

适用材料 Applicable materials |

BOPP,POF,HDPE,LDPE,ETE |

BOPP,POF,HDPE,LDPE,ETE |

BOPP,POF,HDPE,LDPE,ETE |

|

最大放料宽度 Maximum discharge width |

600mm |

600mm |

600mm |

|

最大放卷直径 Maximum unwinding diameter |

500mm |

500mm |

500mm |

|

最大制袋速度 Maximum bag making speed |

40-120pcs/min |

40-120pcs/min |

40-120pcs/min |

|

最大制袋长度 Maximum bag making length |

550mm |

650mm |

750mm |

|

制袋宽度 Bag width |

70-500mm |

70-500mm |

70-500mm |

|

电源电压 Supply voltage |

380V/50HZ |

380V/50HZ |

380V/50HZ |

|

总功率 Total power |

11.0KW |

12.0KW |

13.0KW |

|

外形尺寸 Overall dimension |

8000×1300×1500mm |

8000×1500×1500mm |

8000×1900×1500mm |

|

重量 Weight |

2600kg |

2700kg |

2800kg |

BAG BINDING MACHINE:

This machine is special designed for plastic bag binding .

Standard equipped with 3 groups of Temperature control system and 3 sets of 8mm heat needle device,can bind 3pcs of 8mm hole at same time.Also can add extra temperature control system according to client requirements.

Technical process:

1. Adjust the position of heat needle,make the heat needle located in the middle of the upper mold

2. Turn on the power ,set the temperature, and set the binding time accoding to the bag binding thickness

3. Put the bags under heat needle ,then step the foot pedal

4. The pressing plate automatic descend ,the heat needle automatic ascend,stay after setting time ,the pressing plate automatic ascend ,the heat needle automatic descend.

5、Finished bag binding .

Specifications:

Weight:200KG

Power:1KW

Power supply:220V50HZ

Air supply :0.5MPA

Overall dimension:900*460*1100

Main parameters:

1. Applicable materials: the machine is specially developed for pinhole film and is suitable for producing full version or half version OPP pinhole film.

2. Guide roller width: 1030mm,

3. Unwinding diameter: ≤ 500mm

4. Unwinding width: ≤ 1000mm

5. Winding diameter: ≤ 500mm

6. Winding speed: 150m / min

7. Power supply: 380V ± 5%, 9kw, 50Hz.