Performance and characteristics:

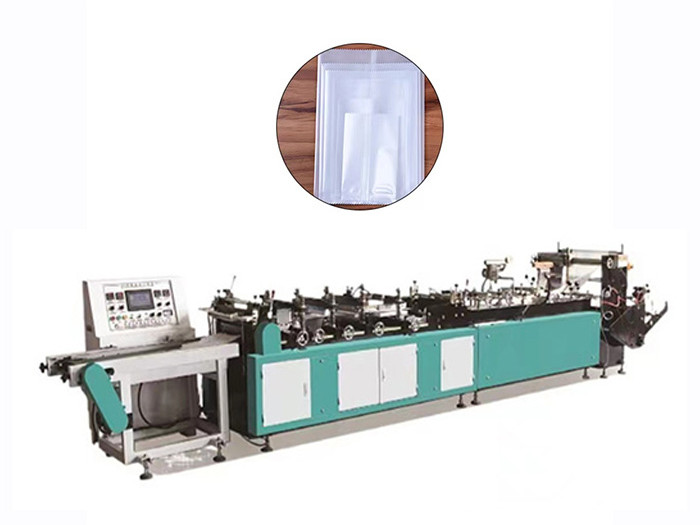

The machine is suitable for automatic sealing, bottom sealing and shearing of flexible packaging composite bags. It adopts computer automatic control, servo motor control, frequency conversion speed regulation, photoelectric tracking, work counting, automatic temperature control, high parking, 2 ironing and sealing devices, firm sealing and leveling technology. (Punching die and tear opening, single film bag sealing device can be added according to user's requirements).

Machine details:

|

Machine part |

Electric part |

|

1.Rewinding device: Rewinding device uses magnetic powder, inflation shaft |

1. The main engine adopts frequency conversion speed regulation (1.5kw), and the frequency converter adoptsBlue |

|

2. Frame: Steel plate structure |

2. Servo motor (domestic) 1 for feeding |

|

3. Cross-cutting tool holder: castings structure |

4. Frequency Conversion Speed Regulation for Traction |

|

5. Using domestic common cutter |

4. Double Photoelectric Tracking and Positioning Device for Edge Rectifier (Zhejiang Julong) |

|

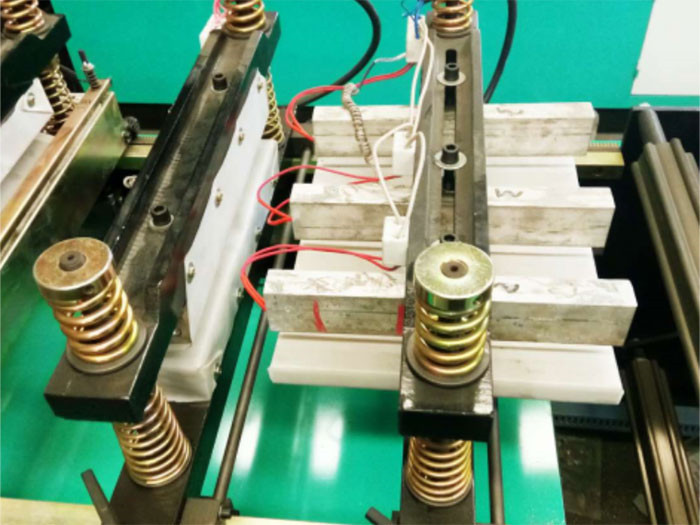

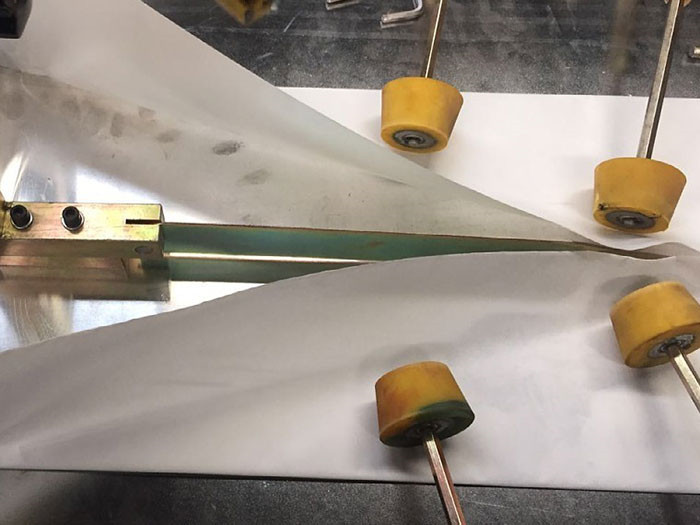

5. Driving axle: slotting with rubber axle 6. Blanking knife: The bottom cover is made of aluminium and visible structure (2 irons and 1 flats) Medium Seal Blanking Knife is made of copper parts |

5. Independent computer control cabinet: automatic counting, automatic alarm to the number. Automatic shutdown function |

|

7. Feeding traction mode: motor driven pulley driving traction rubber shaft |

Computer(touch screen) |

|

8. Maximum substrate width 700 MM, longest truncation length 350 MM |

7. The main engine adopts motor 1.5KW (Shanghai) |

|

9. Total weight 2000kg |

8. The fastest speed of the machine is 260/min (usually calculated by the length of the bag, such as 210 bags per minute, 200 mm long). |

|

10.machine size: length 5.2 m * width 1.4 m * height 1.5 m |

|