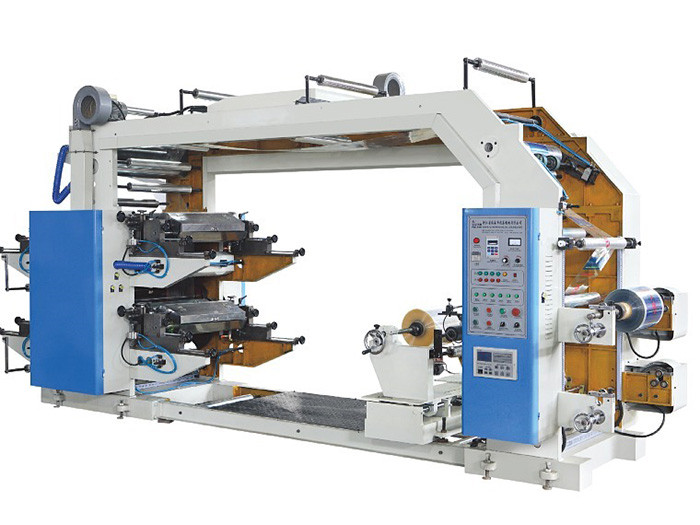

Key Features Description:

1. Easy to operate, easy to put, accurate coloring, long service life

2. Motor, frequency control, power saving and small fluctuation

3. The inking motor will stop automatically when the plate is down, and the inking device will start automatically when the plate is up

4. The ink supply mode is cot scraping

5. Special module spur gear transmission is adopted, and the printing size is accurate,

6. There are two sets of blowing and heating devices, in which the heating adopts the central constant temperature control system and group control

7. The low rod is made of steel and treated by special process, and plated with 5-wire thick hard chromium protective layer

8. Hard oxidation, dynamic balance and static balance treatment for aluminum alloy guide wheel

9. It is equipped with cold air shaping bellows, which can effectively prevent ink adhesion and other defects after printing

10. Clear printing image and accurate folding

11. Printing, folding and dividing into one, high production efficiency and high yield

12. Automatic counter, stop the machine automatically when the material is broken, stop the machine automatically to transport the ink, and stop the ink motor automatically when printing.

13. Printing materials: plastic, web, non-woven fabric.

1. Printing color number:4 colors (any increase or decrease) 4 + 0 3 + 1 2 + 2;

2. Maximum mechanical speed: 90 m / min;

3. Maximum printing speed: 70 m / min;

4. Roller: metal roller;

5. Registration accuracy: longitudinal±0.5mm (manual);

6. Transverse:±0.5mm (manual);

7. Winding and unwinding: the diameter of winding and unwinding is 600 mm;

8. Retracting and unwinding paper cylinder / rubber cylinder: air expansion shaft with diameter of 76 mm (inner diameter);

9. Imprint force: mechanical adjustment;

10. Impression roller:Φ132mm;

11. Drying method: electric heating;

12. Drying power: 15kw;

13. Fan: 0.55kw, 2 units;

14. Main motor: 2.2kW;

15. Main frequency converter: made in China;

16. Ink motor: synchronous motor ink;

17. Ordinary bearing: made in China;

18. One way bearing: made in China;

19. The aluminum alloy guide wheel is treated by hard oxidation, dynamic balance and static balance;

20. Correction system: optional;

21. Tension control system: take in and take out magnetic powder control;

22. Landing plate: 1 set of cylinder device landing plate;

23. Main electrical appliances: Chint or Delixi;

24. Total power (about) 18kw;

25. Print length range: 200 MM-1000 mm;

26. Plate thickness: 1.7 or 2.28mm;

27. Maximum print width: 800mm;

28. Maximum printing width: 760 mm;

29. Printing stick: one for each color, with effective printing length of 300 mm;

30. Tension shaft: optional;

31. Overall dimension (about): length 4.8×width 1.8×height 2.5m;

32. Weight (about): 3 tons.