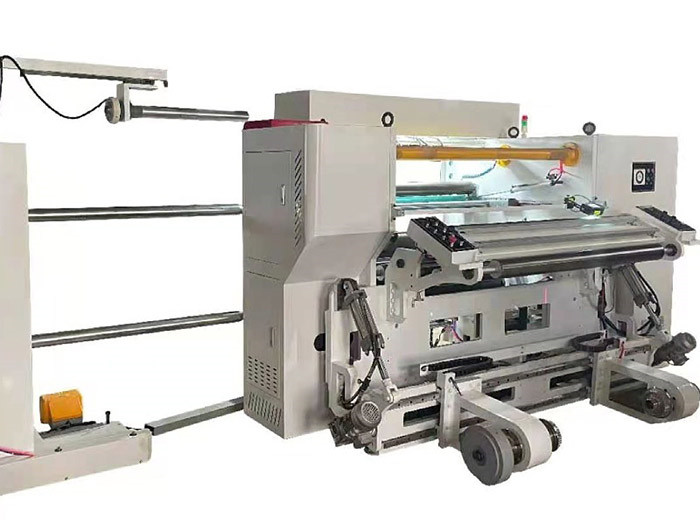

The main technical parameters:

Maximum unwinding diameter:φ800mm

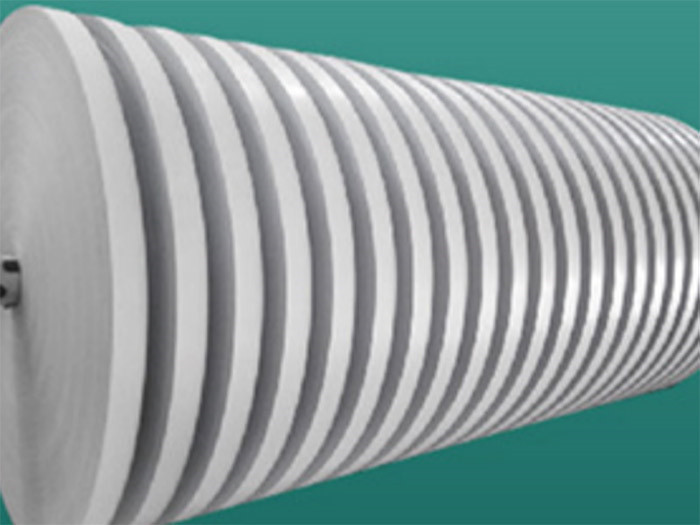

Maximum winding diameter:φ600mm

Unwinding width range:400mm-1600mm

Slitting width:40mm-1600mm

Paper tube diameter for unwinding ;3″(φ76mm φ92mm)

Diameter of paper tube for winding:3″(φ76mm φ92mm)

Maximum mechanical speed:400m/min

Maximum rewinding speed:350m/min

Maximum cutting speed:350m/min

Machine cavity width:1900mm

Correction accuracy:≤0.40mm

Tension setting range:2~30kg

Unwind magnetic powder brake:200N.M

Winding motor power:5.5Kwx2

Traction motor power:7.5kW

Total machine power:20kW

Machine dimensions :2200(L)×4600(W)×1850mm(H)

Machine weight:3800kg

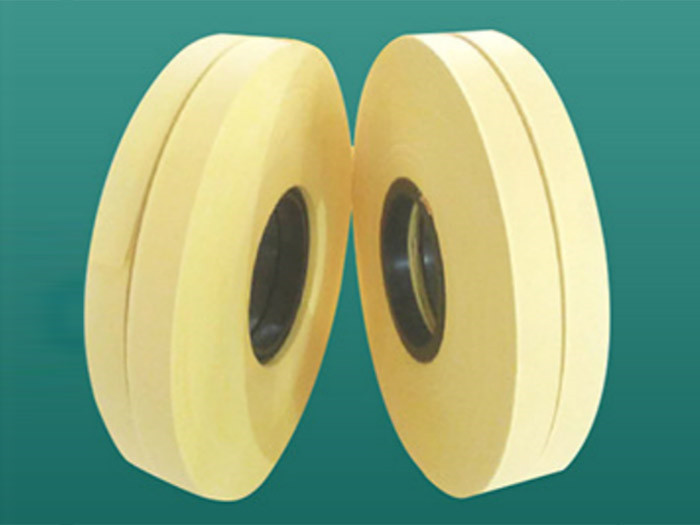

Applicable materials:12-300um,PE、PVC为40um-300um

Film and composite film 12-300um, PE and PVC are 40um-300um

Stickers, paper, anodized aluminum film, aluminized film, aluminum foil, etc.

Structure

●One-piece unwinding rack

●Shaftless pneumatic cone-top unloading rack, manual width adjustment

●LPC horizontal correction mechanism

●Automatic tension control

Features

●Shaftless pneumatic cone-top unwinding rack, fast and convenient up and down.

●With LPC to ensure neat rewinding

●Tension adopts vector frequency conversion and PLC automatically calculates the roll diameter to realize automatic tension control, which makes the tension control of the material film more scientific and accurate

●Pneumatic brake control unwinding makes tension control softer, no residual torque, and high tension control precision

Specifications

●The diameter of the deviation adjusting rollerφ90 mm

●Total length of deflecting roller 1750 mm

●Range of deviation adjustment±20 mm

●Guide roller wall thicknessφ10 mm

●Guide roller length 1650 mm

Features●Adopting a deflecting roller mechanism to adapt to different quality materials

●After the roller is dynamically balanced, the machine has no vibration source and runs smoothly

●Imported high-precision bearings are used to make the rollers stable when rotating at high speeds and reduce the noise

●The surface is equipped with cross lines (effectively avoiding the image of material wrinkles), and oxidation and hardening treatment

Slitting part:

●Flat knife + round knife slitting method

●Flat knife adopts slotted roller to support slitting (suitable for thin materials)

●The circular knife adopts upper and lower bite transmission to cut (suitable for thick materials)

●The edge material is reeled by the edging machine in the slitting part

●6 sets of round knives and 6 sets of flat tool holders.

Rack part:

●Using steel plate, the thickness of steel plate is 40 mm

Pneumatic hydraulic system:

●The machine adopts pneumatic and hydraulic actuators, which are operated by the panel and executed by solenoid valves. The degree of automation is high and labor intensity is reduced.

Electrical control system:

●Using man-machine interface, PLC centralized control, advanced technology

●Man-machine interface, display and set host speed, rewind length, set unwind and rewind tension, taper setting