Characteristics:

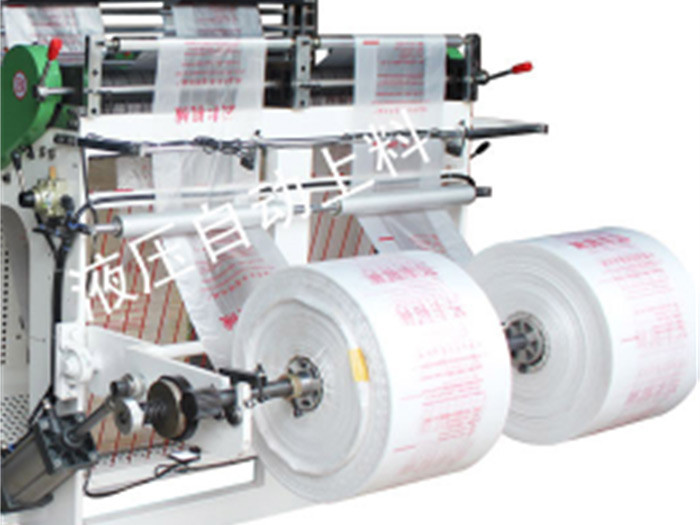

1. This machine can produce natural color and printed vest bags with HDPE, LDPE and biodegradable material [corn starch] barrel film as raw materials. It adopts computer programming control system and servo motor to automatically determine the length, which can be completed at one time from feeding, back sealing, cutting, punching and conveying.

2. Equipped with two servo motor control systems, computer control, LPC LCD display and Panasonic photoelectric eye tracking control, the operation is intuitive and convenient, and two color printing bags can be produced at the same time.

3. The main machine adopts imported frequency converter to simulate speed regulation and automatic feeding system to make bag making stable and accurate sealing and cutting. Automatic punch folding device, conveyor belt bag feeding function, easy to collect.

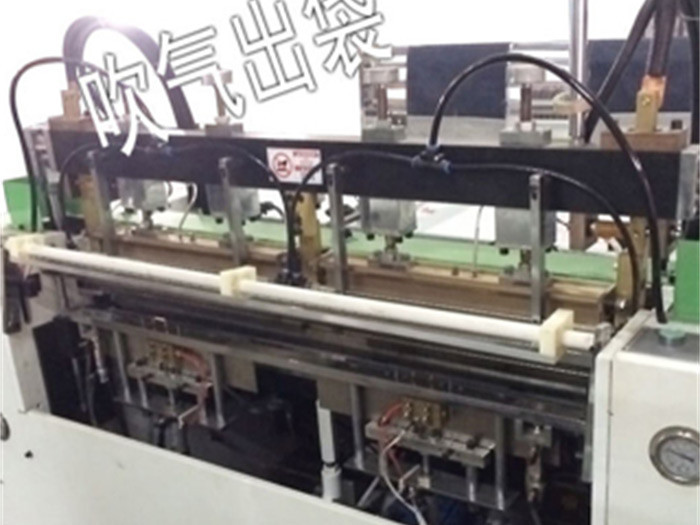

4. Swing discharging system, combined with the integral design of the bag bottom, the bag collection is neat and the clamping and punching position is accurate.

5. The cutter adopts current independent heating, and the high-precision temperature controller automatically controls the temperature, which is convenient to operate and accurate.

6. The whole machine adopts IC electronic circuit automatic control and socket design, which is easy to change and install; It also has the functions of no material, material breaking, material blocking and shutdown.

7. With years of leading technology in the plastic machinery industry, our company has made a breakthrough in research and development, and created a new generation of high-speed bag making machine and punching machine. New and old customers are welcome to visit and test the machine.

Main technical parameters:

|

1 |

Model |

YF-HS450×2 |

|

2 |

Max width of bag |

200-400×2mm |

|

3 |

Max length of bag |

320-600×2mm |

|

4 |

Thickness of bag |

0.008-0.1mm |

|

5 |

Bag making speed |

200-350pcs/min×2 |

|

6 |

Air compressor |

10P |

|

7 |

Total power |

16kw |

|

8 |

Supply voltage |

Ac380V/50Hz |

|

9 |

Machine weight |

2500kg |

|

10 |

Dimensions |

6500×1600×1800mm |