Applicable materials:

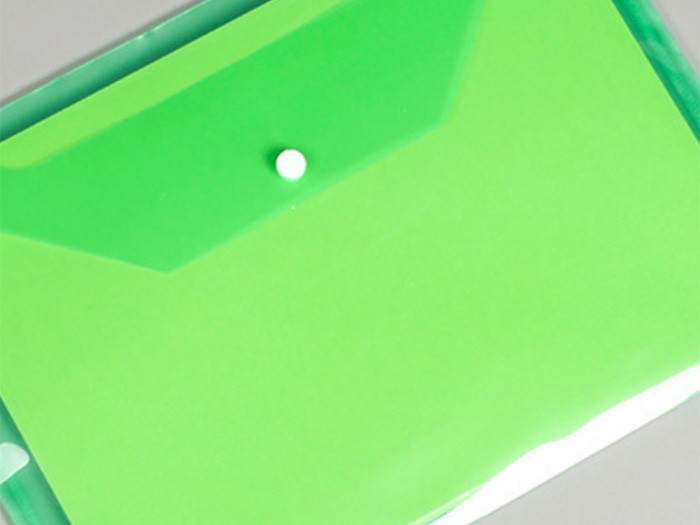

The machine is a professional manufacturer of file folders and w209 button bags. PP sheet coil is used to make file folders and button bags without flanging sealing.

2、 Technical parameters:

(1). Applicable material: PP sheet can be used to make 209 button bag and E310 folder without flanging sealing.

(2). Effective manufacturing speed:

E310: 70 ~ 100 sheets / min

209 buckle bag: 40-50 pieces / minute.

(3). Effective bag making width: ≤ 240mm

(4). Effective bag making length: ≤ 360mm

(5). Effective sealing and cutting thickness: 0.1mm ~ 0.2mm

(6). Maximum unwinding diameter: Φ 600mm

(7). Overall dimension: 8500 × 1300 × 1350(L × W × H)

(8). Working voltage: three-phase AC380V 50Hz 9kw

(9). Mechanical weight: 2.5t

3、 Main configuration of machinery:

1. Fixed length and main control:

(1). It adopts Taiwan Yonghong PLC as the main control, Taiwan "Shilin" servo fixed length traction, and color touch screen man-machine operation interface.

(2). Equipped with automatic counting, advance alarm, arrival shutdown, number display, high-level shutdown, automatic feeding, ultrasonic control and other functions.

2. Host:

The "piner" vector frequency converter is used as the speed regulation control of the main engine.

3. Feeding:

The swing arm surplus feeding structure is adopted, and the "piner" vector frequency conversion follows the speed regulation feeding. It is equipped with two trimming cutters and two pneumatic wire pressing knives.

4. Unwinding part:

(1). Equipped with automatic binocular automatic deviation correction control system.

(2). The maximum unwinding diameter is 600mm.

(3). The maximum discharging width is 700mm.

(4). The unwinding shaft is a three inch air expansion shaft and a mechanical shaft.

(5). With manual magnetic particle tension control system.

5. Receiving:

Belt type material receiving is adopted and controlled by "piner" vector frequency conversion speed regulation.

6. Sealing part:

Wire sealing ultrasonic (domestic) adopts lower mounted mechanical power pressing.

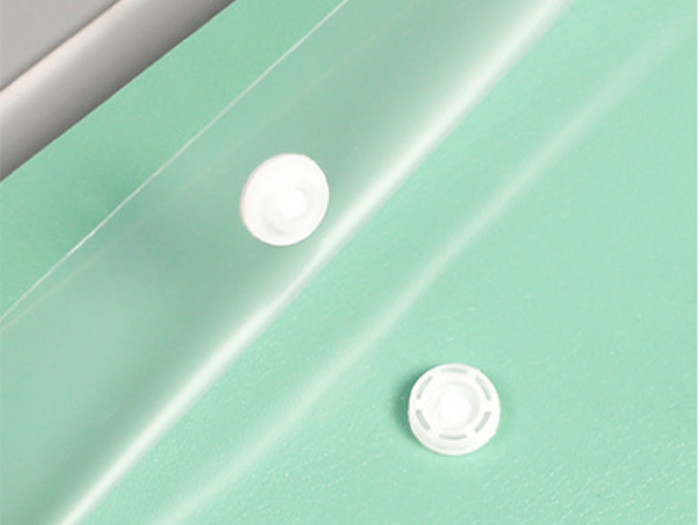

7. Automatic fastening part:

This part adopts an integral welded frame, which is composed of the following devices:

(1). A pair of servo driven fixed length pulling devices are equipped with longitudinal and transverse moving guide rails

(2). Two automatic fastening devices

8. Other attached devices:

(1). A pair of semi-circular die and special-shaped hole die

(2). A pair of pneumatic punching dies

(3). AB receiving platform

(4). One set of hot stamping device (last sample)

(5). One set of concave punching die (for 209) (according to the sample bag of the demander)

(6). One set of semi-circular punching die (for 209) (according to the sample bag of the demander)

(7). A pair of 1.5mm diameter round hole molds (for 209)

(8). Equipped with electric eye tracking

IV Supporting facilities: (please be responsible by the user)

1.Power supply: Three phase four wire AC 380V 50Hz and grounding wire. (requirements for grounding wire: the reinforcement or steel pipe with a diameter of 30 ~ 50mm and a length of more than 1.5m shall be directly driven into the ground and led out with a conductor of 4mm2 at the upper end). It is absolutely prohibited to connect the zero wire to the machine.

2. Installation site: The ground hardness is required to ensure that after the installation and commissioning of the equipment, there will be no foundation settlement during operation, which will make the equipment operate abnormally or damage the equipment.

3. Air supply pressure: 5kg/cm ² Above constant pressure.

4. Standby power of the whole machine: 20KW