Notes:

1. KPEB-700-A model Kraft paper bottom gusset glue applied courier bag making machine, Kraft paper courier bag machine in short. We use single layer Kraft paper and apply glue in some part crosswise and lengthways, and then heat press and seal into a finished courier bag product with bottom gusset. We only need to use ordinary Kraft paper on this machine. There have to be a cross width code mark which size is 5x40mm, please propose if you can’t print it; ( We can equip a set of online stamp unit. There are ten stamps in total, six of them are used to make the positioning mark of bag width, three will install on the machine and the other three send together with the spare parts; and the rest four are used to stamp the company information, two will install on the machine and the other two send together with the spare parts.

2. The glue for second timeheat seal after foldingmust be non-stickytwice openingglue after cooling or air drying.

Ⅰ. Brief Introduction:

1. This machine is special designed for making bags which use Kraft paper and stick by glue.

2. Bag making method: Applying glue on the Kraft paper flap small folding part of the flaplengthways, and applying glue on the side of the bag crosswise,and sealing the small folding part on the flap,and roller folding from one side or from double sides, and positioning dispense glue on the bottom of bag apply red strip, making bottom gusset, three times of mechanical heat sealing and one time of mechanical cold pressing,one time of lengthways heat sealing, rolling the easy-tear line and cold cutting etc. Finally finished in to a standard Kraft paper bottom gusset bag.

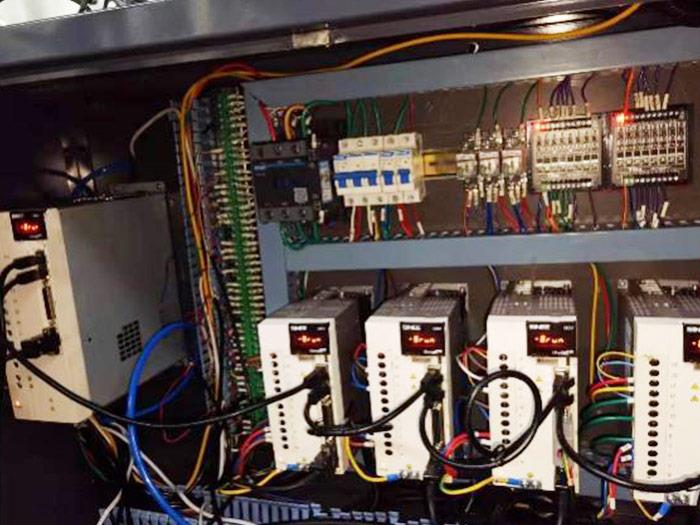

3. This machine uses multi point advanced motion controller technology. It is controlled by computer program from film unwinding to cutting. This machine is a high-quality, easy-operational and professional one to make good-looking a, durable and environment-friendly bags.It can make the bags as follow.

Technical Parameters:

1. Function:

This machine can make single layer Kraft paper bottom gusset bag in one line or two lines, it has functions like applying red strip, rolling easy tear line, small turn up on the flap,positioning dispense glue on the bottom of bag and pressed sealing etc.

2. Bag making size:

When making in one line,450mm(bag width)X600mm(bag height,with flap);

When making in two lines,400mm(bag width)X350mm(bag height, with flap);

Depth of bottom gusset30mm, it can make two gusset at the same time

when making small bags.

3. Bag making speed:

The maximum speed of machine is 25 meters/min, that is 50 pcs/min if make bags which width is 500mm.

The highest mechanical executive speed is 70 cuts/min.

One line,70 pcs/min;

Two lines,140 pcs/min

4. Machine size:

Length 23 meters, height 2.2meters, width 4 meters.

Supporting facilities:(The buyer supply)

1. Power: 3-phase 4-wire AC380V 50Hz and ground earth (notes: The steel diameter must be 30-50mm, the length is more than 1.5m directly put into the ground, and there should be a line conductor which more than 4 square mm leads to upside of ground)Strictly forbid the null line connecting the machine.

2. Installation filed:The buyer must make sure the ground is hard enough to support the machine run stably after installation and debugging. And to avoid the ground settlement that make the machine work abnormal or broken.

3. Air pressure:5 kg/cm² constant air pressure

4. Power required:

Ⅴ. Business Item:( See in sales and purchase contract)

Price: CNY 430000 yuan with value added tax.

Delivery time: 60 days.