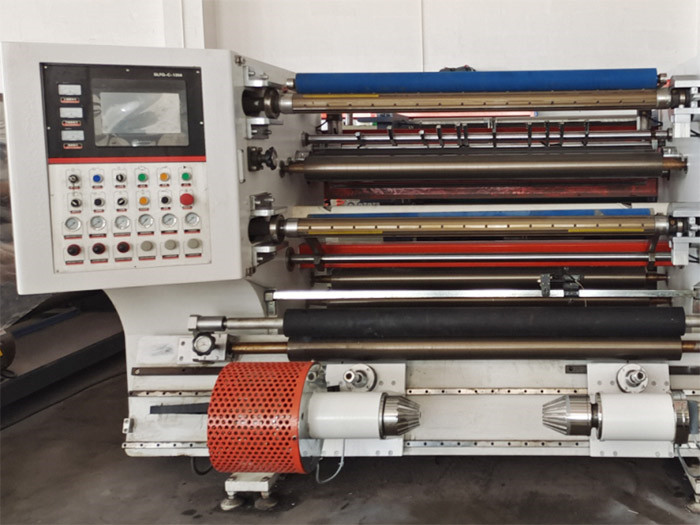

Performance and characteristics

1. The machine adopts DC motor to maintain smooth operation during acceleration; (variable frequency speed regulation can also be adopted)

2. Automatic meter counting, alarm and other functions;

3. The winding adopts a inflatable shaft structure, which is convenient for loading and unloading;

4. The unwinding adopts photoelectric automatic deviation correction system, so that the irregular materials can be cut normally

5. Automatic discharge device for waste edge of flat knife longitudinal cutting

6. Hydraulic shaftless feeding, 3 inches.

1、Technical parameters

1. Width: 1300 type

2. Slitting thickness: 20g-300g / m2 (depending on different raw materials)

3. Maximum diameter of raw material unwinding:φ700mm

4. Maximum diameter of raw material winding:φ450mm

5. Maximum width of raw material for slitting: 1300mm

6. Double ball slip shaft of winding machine:φ75mmx30mm

7. Number of reeling shafts at the same time: 2 (double shaft reeling)

8. Deviation correction accuracy:±0.5mm

9. Slitting accuracy:±0.5mm

10. Speed: 10-300m / min

11. Total power: 7KW

12. Body color: white cover white (other colors are optional)

13. Adopt automatic photoelectric deviation correction (depending on different raw materials and customer specific requirements)

2、Machine configuration

1. Unwinding part:

(1) The frame adopts steel plate structure

(2) Magnetic particle tension control: tension control range: 5-100n M

(3) One set of Ningxia 10kg brake is used for tension magnetic powder

(4) The feeding shaft adopts the form of feeding without shaft, 1

(5) The transmission guide roller adopts aluminum guide rod and is subject to dynamic balance treatment

(6) The base material can be adjusted left, right and parallel: manual operation

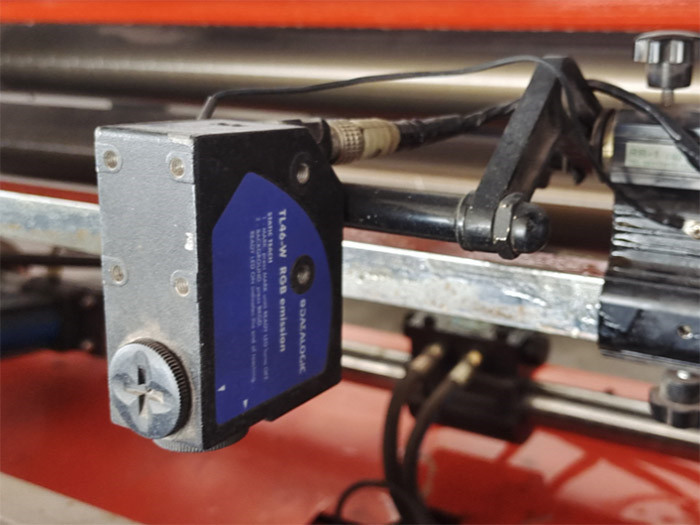

(7) 1 set of photoelectric deviation correction system

Deviation correction accuracy:±0.5mm

Deviation correction analog deviation correction motor drive 1 set

One of them

2. Host part

(1) The frame adopts 50# high-quality steel plate structure

(2) 45 * square steel support

1) Drive and transmission mechanism:

(3) The active adopts the combination of motor and variable speed wheel

(4) The main motor adopts a speed regulating motor of 5.5kW, 1 set

(5) The frequency converter adopts Shenzhen Boteng frequency converter Co., Ltd. (5.5kW)

(6) The transmission adopts the combination of belt pulley and sprocket

(7) Guide roller: adopt aluminum alloy guide roller and conduct action balance treatment

(8) Aluminum guide roller adopts hard oxidation specification:φ100 1400mm

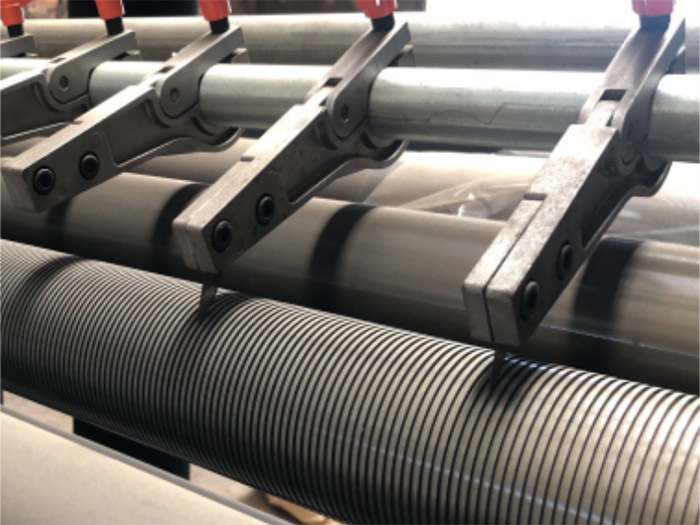

2) Traction device:

(1) Structure type: active traction pneumatic compression type

(2) The pressing mode is controlled by air cylinder

(3) Compression cylinder specification:φ50 * 25 2 pcs

(4) The pressing roller adopts rubber roller (specification:φone hundred and ten×1400mm) 1

(5) The driving roller adopts rubber roller (specification:φone hundred and twenty×1400mm) 1

(6) Driving mode: the main motor drives the main transmission shaft, and the main shaft drives the driving roller for traction

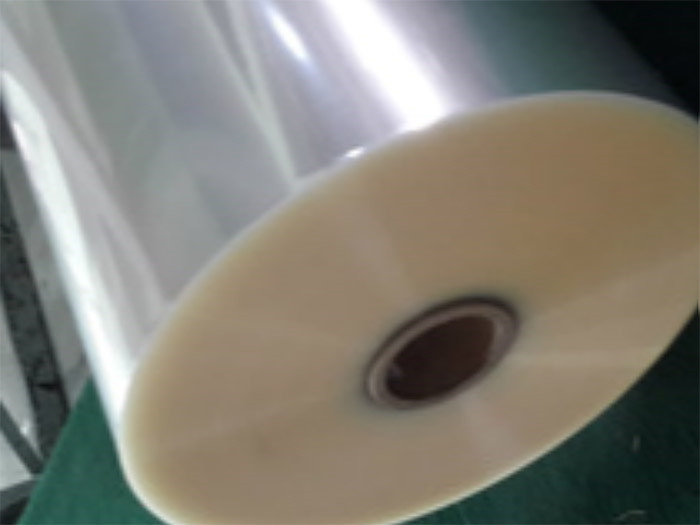

3. Winding device

(1) Structure: inflatable shaft (single shaft winding is also available)

(2) Adopt tile type inflatable shaft (specification:φseventy-four×1400mm) 2

(3) Ningxia magnetic powder clutch 5kg 2 pcs

(4) Compression mode: cylinder top sleeve structure and two back pressure shaft devices are adopted

4 waste discharge device:

(1) Discharging method: blowing waste

(2) The main motor adopts one three-phase asynchronous motor (specification: 0.75KW)

5. Control part: 1 piece

(1) The control system of the machine can be roughly divided into three parts: host control, tension control and other control.

(2) Host control: (Siemens PLC + HMI)

(3) Tension control: the unwinding tension, winding tension and control speed range are wide. It has excellent performance at low speed and high speed, and the winding effect is excellent.

(4) Attached with electronic meter counter; Alarm shutdown; Automatic length determination.

(5) The cutting length can be preset for shutdown

6. Supporting facilities: (the user is responsible for it)

(1) Power supply: three-phase three wire air switch: voltage 380V 50Hz

(2) 1.5KW air compressor

|

Model |

800 |

1100 |

1300 |

1600 |

1800 |

|

Width of unwind |

≤800MM |

≤1100MM |

≤1300MM |

≤1600MM |

≤1800MM |

|

Max.diameter |

≤1000MM |

≤1000MM |

≤1000MM |

≤1000MM |

≤1000MM |

|

Diameter of rewind |

≤650MM |

≤650MM |

≤650MM |

≤650MM |

≤650MM |

|

paper core size |

76MM |

76MM |

76MM |

76MM |

76MM |

|

Speed |

0-300m\min |

0-300m\min |

0-300m\min |

0-300m\min |

0-300m\min |

|

Motor power |

5.5KW |

5.5KW |

5.5KW |

7.5KW |

7.5KW |

|

Cutting width |

0.5-800MM |

10-1000MM |

20-1300MM |

25-1600MM |

30-1800MM |