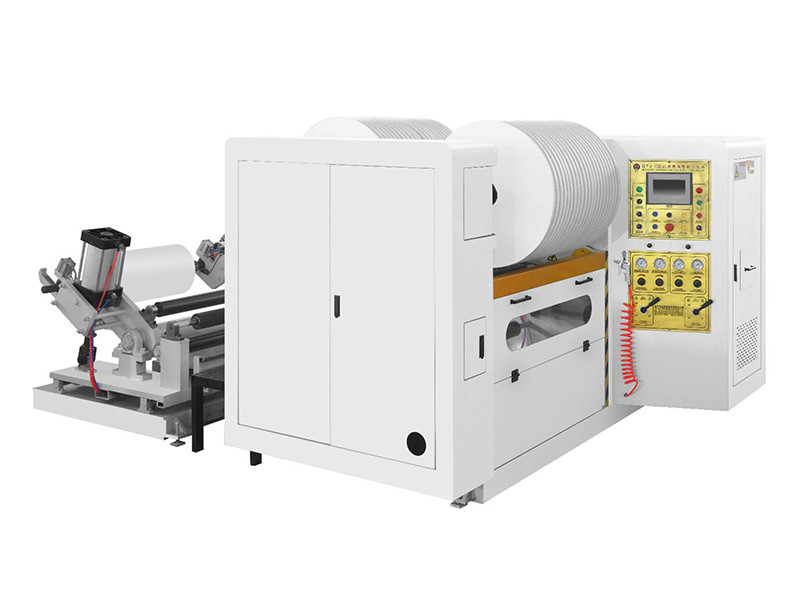

Application: The machine is suitable for slitting and rewinding all kinds of non-woven fabrics, melt blown fabrics, hot air cotton, PVC \ pet \ BOPP \ polyester film reel materials.

Characteristic:

The machine adopts computer control, infrared photoelectric tracking and deviation correction system, and the winding tension is controlled by magnetic powder clutch through PLC touch screen to realize automatic tension control. The unwinding tension is controlled by magnetic particle brake and automatic tension. The winding shaft adopts air expansion shaft. The frequency converter controls the working speed of the whole machine and is equipped with an automatic meter counting device. The number of meters can be set arbitrarily to slow down and shut down, and the minimum diameter of unwinding can be set to shut down automatically (to prevent waste caused by secondary threading) The utility model has the advantages of smooth incision, neat winding end face and convenient subsequent processing.

Main components of the machine:

The machine is composed of deviation correction and unwinding mechanism, slitting mechanism, winding mechanism, transmission mechanism and electrical control.

Main configuration and specifications of each mechanism:

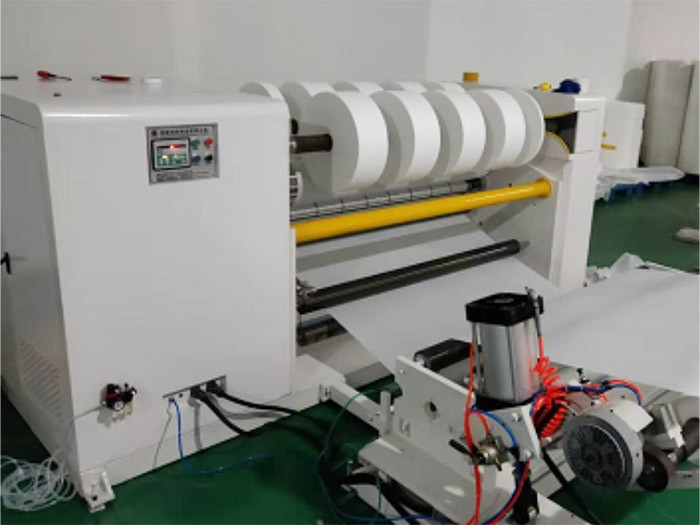

Unwinding mechanism:

The mechanism is equipped with manual vertical and horizontal deviation adjustment, which can eliminate the tension and wrinkling at both ends of the raw material due to thin thickness or out of round paper core.

The high linear magnetic powder brake is used as the unwinding tension actuator, the output torque is balanced, and the tension fluctuation can be reduced to the lowest state.

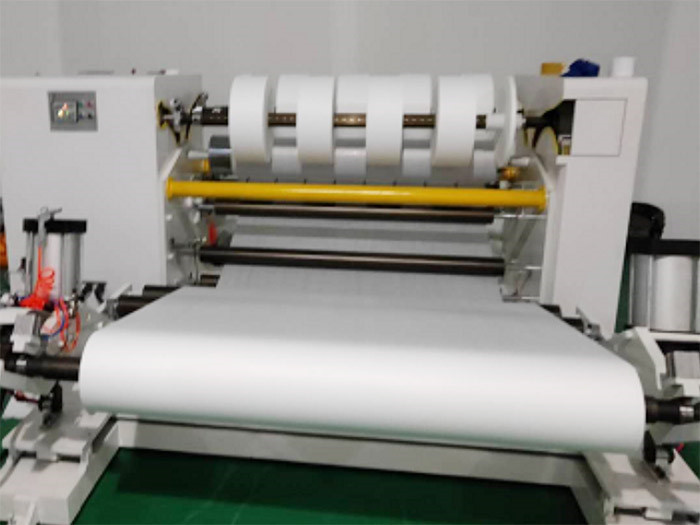

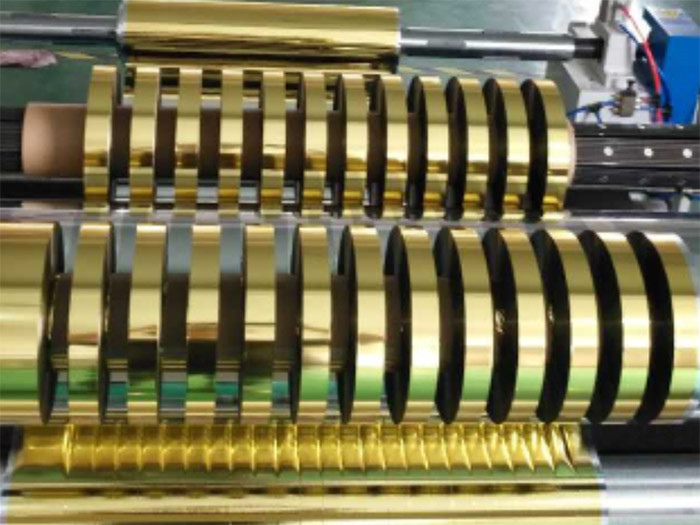

Slitting mechanism:

The mechanism adopts round knife slitting, with neat incision and long service life. The upper and lower knife shafts of slitting are subject to quenching and tempering treatment, and the speed matching between the upper and lower knife shafts is carried out by gears. Rotate the hand wheel to lower the knife, and continue to rotate to realize automatic knife leaning.

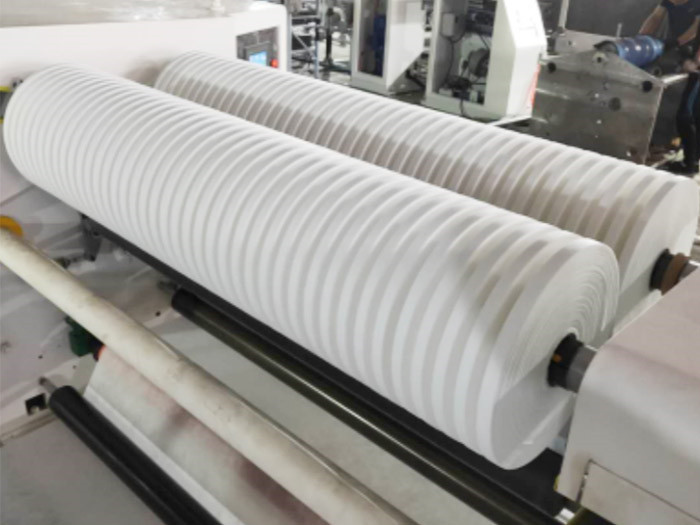

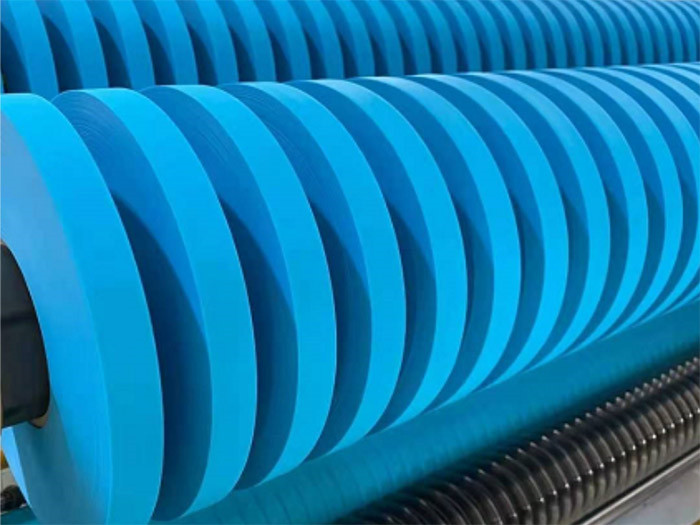

Winding mechanism:

The mechanism adopts left and right axle double axle winding, and is equipped with pressure arm to balance the internal and external pressure of winding. Two magnetic powder motors are used to control the winding tension, and the uniaxial tension is arbitrarily adjustable, with automatic tension control.

Transmission mechanism:

The driver is used to control the operation of the main motor, which is convenient and fast, and the speed adjustment is too soft and stable.

Driving mode: general frequency conversion regulation, frequency conversion motor drive.

Main electrical appliances:

Centralized electric cabinet control, beautiful and easy to operate.

Self care:

1.50hz, 380V three-phase five wire power supply

2. Foundation treatment

3. Equipment for installation and raw materials and auxiliary materials for commissioning

|

Serial number |

Name |

Configure |

Quantity |

Place of Origin |

|

1 |

Unwinding material loading card |

3in air shaft |

1pc |

Ryan |

|

2 |

Main motor |

4KWvariable frequency motor |

1set |

shanghai |

|

3 |

Host control |

4KWvariable frequency motor |

1set |

Delixi |

|

4 |

Deviation correction guidance |

Linear bearing |

4pcs |

Zhejiang |

|

5 |

Substrate orientation |

Synchronous motor |

1set |

Chongqing |

|

6 |

Deviation correction detection |

Photoelectric eye |

1set |

infrared homing |

|

7 |

Tension detection |

PLC built-in encoder output signal |

1set |

|

|

8 |

Slitting mode |

Round knife |

5sets |

Self production |

|

9 |

Winding tension |

50N.Mmagnetic particle motor |

2set |

Self production |

|

10 |

Winding control |

PLC built-in tension control system |

1set |

Siemens |

|

11 |

Rewind air shaft |

3in |

2pcs |

qiangguang |

|

12 |

Edge treatment |

fan |

1set |

qiangguang |

|

13 |

Complete machine controlPLC |

Touch screen man-machine interface |

1pc |

Kunlun Tongtai |

|

14 |

Main electric appliance |

Button, touch, air switch, etc |

some |

Chint |

|

15 |

Description of main control system |

ension controller, deviation correction controller, frequency converter, etc |

Each 1 pc |

manufacturer |