The machine is mainly suitable for slitting PP PET plastic film.

Feature:

1.The machineusecenter winding and the surfacedrum rewinding.

2. Web guide system, automatictension control system withmagnetic powder brake andservo motor rewinding

3. Machine with meter counter, automatic stop

4. FrequencyInvertercontrolmain motor

Main technical parameter :

|

Model |

FQJ-600 |

|

Width of roll material |

600mm |

|

Max. Diameter of roll material |

1000mm |

|

Max. Diameter of rewinding roll |

650mm |

|

Min. Width of slitting |

8mm |

|

Slitting material thickness |

0.1-0.5MM |

|

Slitting Speed |

0-300m/min |

|

Total Power |

9kw |

|

Overall dimension ( L x W x H mm) |

2200x2100x1400 |

|

Weight |

2600kg |

Mahchine Main Parts :

The machine with unwinder , web guide , slitting system , rewinding unit ,transmission system ,electric control part , etc.

Specification:

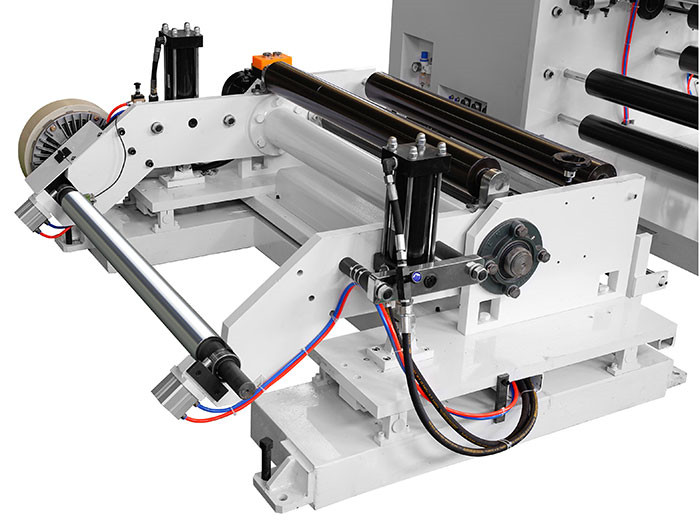

1. Unwinder

A. The machine with Manual horizontal alignment , Eliminates tension and wrinkles caused by the thick ends or uneven cores of the raw materials

B. The high linear magnetic powder brake is used as the unwinding tension actuator. The output torque is balanced, and the tension fluctuation can be reduced to the lowest state. The Siemens PLC automatically detects and calculates the size of the material through online and automatically controls the unwinding tension output.

C. Loading Materila,pneumatic lift loading(Optional Unit)

D. Air Shaft Unwinder,100NM magnetic powder brake tension controled by PLC

E, Web Guide Control Ssyem

2,Slitting System

The machine uses a round knife to cut, the incision is neat, and the service life is long. The upper and lower knife axes of the slitting are widened, and the speeds of the upper and lower knife shafts are matched by the gears. Rotate the hand wheel to implement the knife, and continue turning to achieve automatic knife.

A, Slitting shaft , 1 set Top knife shaft and 1 set bottom knife shaft

B, Locking device: With a rapid tool setting device, it can lock the upper knife shaft to avoid cutting quality problems caused by the upper and lower knife disengagement or movement.

C, High-pressure fan through the blowing pipe diversion, the waste edge come out

D, 30MM Main wall plate: The use of steel wall panels, effective damping, to facilitate the smooth operation of the machine at high speed

E,φ100×650mm Guide roller: chrome plated, polished

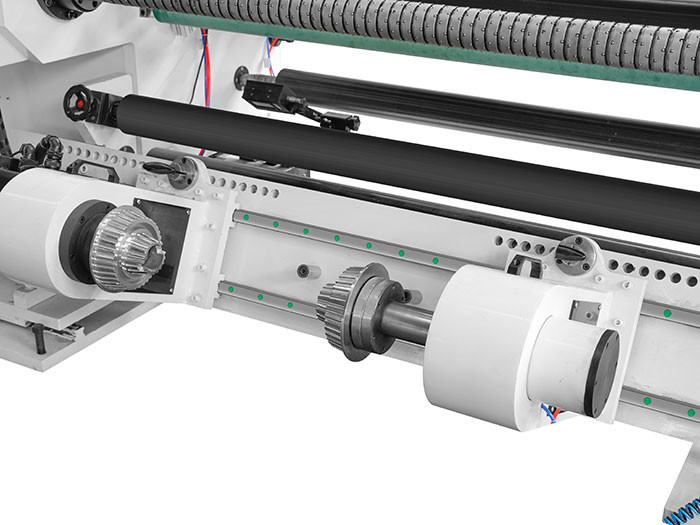

3, Rewinding Unit

A, This machine adopts two-axis rolling of the left and right axles. It is equipped with a pressure arm to balance the pressure inside and outside the winding. The drive adopts two frequency conversion vector motors, the uniaxial tension is arbitrarily adjustable, and the winding tension increases with the increase of the winding volume. The winding volume is automatically calculated by the PLC and the control tension is automatically calculated.

B, Servo Motor control rewinding,Slip shaft winding,and paper core PLC control tension.

4, Driving unit

A, The inverter is used to control the 4KW main motor operation, the speed of the lift is convenient and fast, and the speed adjustment is excessively soft and steady.

5, MainElectrical Part

A,Centralized control of the cabinet, beautiful and easy to operate. PLC automatic tension control

B,Onemeter counter , real-time linear speed real-time, meter meter auto stop function (with deceleration stop function, remember meter basically no error)

C, Button,Contactor,air switchair