1.Features:

(1) Method: Central impression for better color registration. With the central impression configuration, the printed material is supported by the cylinder, and greatly improving color registration, especially with extensible materials.

(2)Structure: Wherever possible, parts are communized for availability and wear-resisting design.

(3)Dryer: Hot wind dryer, automatic temperature controller, and separated heat source.

(4)Doctor blade: open type assembly for high-speed printing.

(5)Transmission: Hard gear surface, high precision Decelerate Motor, and encoder buttons are placed on both control chassis and body for operations convenience.

(6)Rewind: Micro Decelerate Motor, drive Magnetic Powder and Clutch, with PLC control tension stability.

Gearing of Printing cylinder: repeat length is 5MM

|

Machine model |

SMH-CI-6600 SMH-CI-6800 SMH-CI-61000 SMH-CI-61200 |

|

Max.material width |

600mm 800mm 1000mm 1200mm |

|

Max printing width |

560mm 760mm 960mm 1160mm |

|

Suitable for material |

PAPER:15~300g/m2 NONWOVEN: 15-120G、PVC:10~120μm、OPP:10~100μm、BOPP:10~100μm、PE:15~150μm,NY:10~120μm.PET:10~100um,CPP:10~100μm |

|

Colours |

(6 Colours) |

|

Printing length |

300-1000mm |

|

Machine speed |

(200m/min) |

|

printing speed |

150-180m/min |

|

printing precision |

±0.1mm |

|

Plate thickness |

1.7mm ( if different thickness, please note us) |

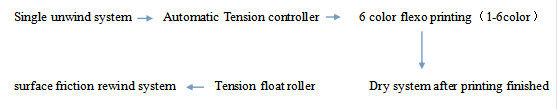

2. Production technology:

3. Machine compose:

|

1.Automatic loader for unwind system |

1 Set |

|

2.Central impression6 color flexo printing machine |

1 Set |

|

3.Dry apparatus between each color |

1 set |

|

4.Dry apparatus after printing finished |

1 Set |

|

5.surface friction rewind system |

1 Set |

|

6.Automatic EPC |

1 Set |

|

7.Electronic control system |

1 Set |

|

8.Automatic unloader forrewind system |

1 set |