Application:

This machine is suitable for slitting cellophane, pet, OPP, CPP, PE, PS, PVC, computer anti-counterfeiting labels, electronic computers, optical materials, film rolls, foil rolls, various paper rolls, film rolls and various materials after printing.

characteristic:

一.Host part:

1. The main structure of the equipment is made of cast iron and steel plate (the casting is processed twice and fixed)

2. The spindle drive rod is made of seamless steel pipe. After quenching and tempering, surface hardening, plating, dynamic balance processing

3. The guide rods are metal rods (aluminum alloy material) and rubber rods (NBR material)

4. The driving mode of the main machine and the receiving material is synchronous wheel and synchronous belt

二.Discharging mechanism

1. The discharging mechanism is a connected discharging frame

2. Install movable support, and the moving device is linear guide rail (Taiwan)

3. No axis air pressure lifting is adopted for discharging, which effectively saves labor and is easy to operate

4. It is equipped with a set of deviation adjusting device, which can be adjusted by hand wheel

5. The unwinding tension actuator is Taiwan magnetic powder brake and American Toledo tension sensor

6. Taiwan BF brand is used to correct the deviation, so as to achieve the effect of edge and line following

三.Winding mechanism part:

1. The receiving shaft is equipped with two pneumatic slip shafts controlled by electric proportional valve

2. The locking mode adopts pneumatic control

3. The winding tension is controlled by FESTO electric proportional valve imported from Germany

4. The roll can be customized according to the customer's requirements

5. The cutter adopts automatic control and is equipped with 10 cutter holders

6. Equipped with 1 set of waste blowing device

7. Equipped with a set of finished product unloading rack

四.Electrical mechanism part:

1. One Yaskawa vector frequency converter from Japan is used for the frequency conversion of the main engine

2. The main servo motor is Taiwan Danma motor

3. Two Japanese Yaskawa vector frequency converters are used for receiving frequency conversion

4. Two sets of Taiwan Danma motors are used as the receiving servo motors

5. LPC adopts analog control, servo motor drive and CCD probe control

6. The imported PLC is used to achieve accurate and stable control function, and the true color touch screen makes the image display simple and beautiful. Dialogic parameter setting environment can start the operation without complicated setting: users only need to input the thickness, width, density, diameter and speed of raw materials before starting the machine, and the next work is automatically calculated by the computer

Main technical parameters:

|

Material width |

1300mm |

|

Material diameter |

Ø800mm |

|

Rewind diameter |

Ø600mm |

|

ID of paper tube |

3’’ |

|

Slitting speed |

10-400 m/min |

|

Correction accuracy |

≤0.1mm |

|

Min.slitting width |

50mm |

|

Total power |

12KW |

|

Machine weight |

4500kg |

|

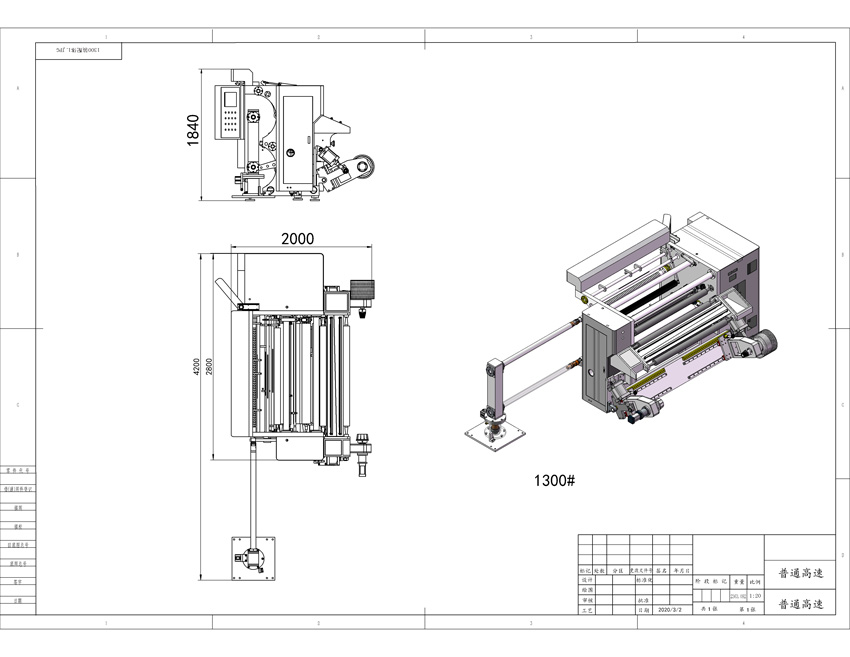

Machine dimension |

2000mm×4200mm×1840mm |

Standard parts:

|

PLC |

Germany siemens |

|

Main servo driver 1pc |

Japan yaskawa |

|

Rewind servo driver 2pcs |

Japan yaskawa |

|

Touch screen |

Beijing kunlun tongtai |

|

Correction ccd probe |

Puliyuan(taiwan) |

|

Rectifying thruster |

Puli yuan (Taiwan) |

|

Correction Controller |

Puli yuan (Taiwan) |

|

One main servo motor 4kw |

Danma (Taiwan) |

|

Receiving servo motor 2 pieces 4kw |

Danma (Taiwan) |

|

Discharge magnetic powder |

Weizheng (Taiwan)

|

|

Discharge tension sensor |

Toledo (USA) |

|

Pneumatic components |

Airtac (Taiwan)

|

|

bearing |

NSK(japan) |

|

Receiving pneumatic slip shaft |

Changyin (Shanghai) |

|

Electric proportional valve |

FESTO (Germany) |

|

Low voltage electrical apparatus |

Schneider (France) |

|

switch button |

Schneider (France) |

|

Material receiving platform |

self-made |

|

Waste edge winder |

self-made |

|

Automatic pushing |

Airtac (Taiwan) |

Spare parts:

|

01 |

inner hexagon spanner |

1 |

05 |

Oil gun |

1 |

|

02 |

Adjustable wrench |

1 |

06 |

Air gun |

1 |

|

03 |

"One" screw driver |

1 |

07 |

Air nozzle |

2 |

|

04 |

Cross shaped screw driver |

1 |

08 |

Operation instruction |

1 |

Optional:

|

1 |

6 "slip ring (34mm) |

|

2 |

Flat turret (10 sets as standard) |

|

3 |

Waste edge winder |

|

4 |

Change the rectification brand to German e + L or BST

|

|

5 |

Automatic pushing device for material receiving (Taiwan Airtac) |

|

6 |

Add a set of motor and frequency converter for material receiving |

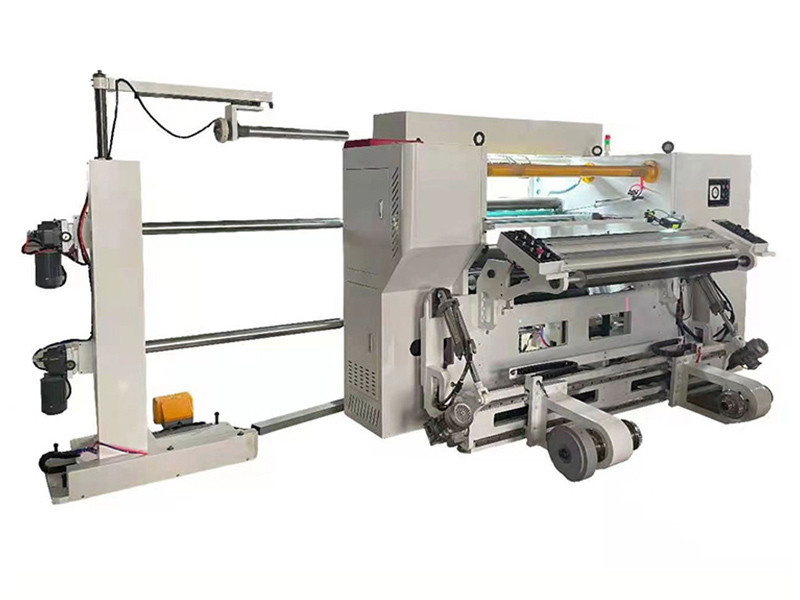

Machine parts photo: