|

Item name or item |

Specification and model |

QUAN |

UNIT PRICE |

AMOUNT |

|

|

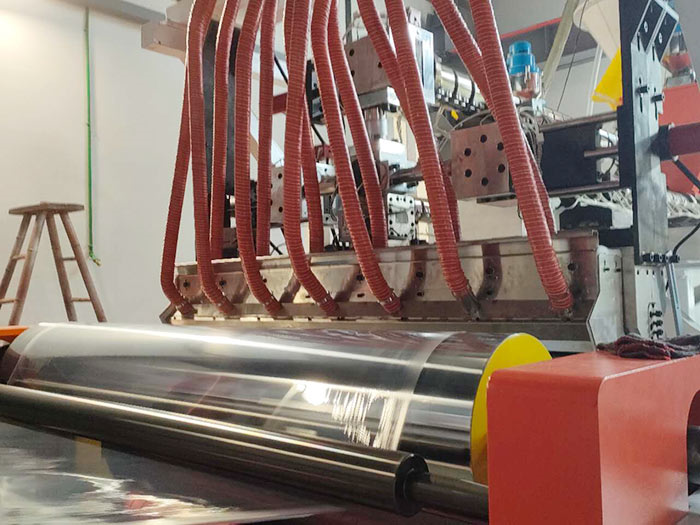

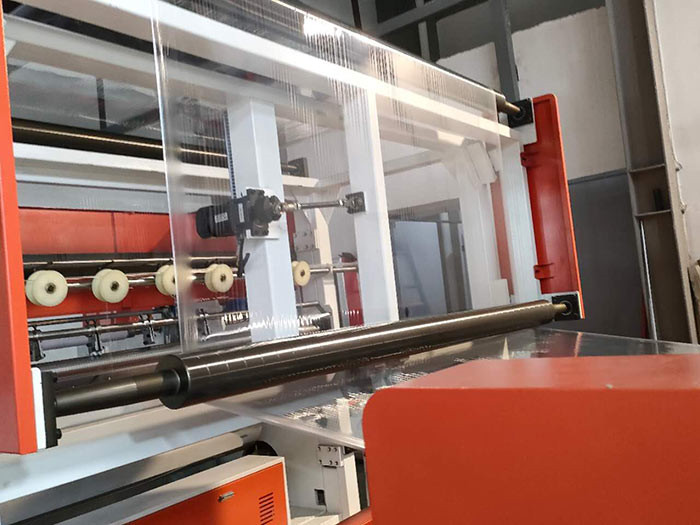

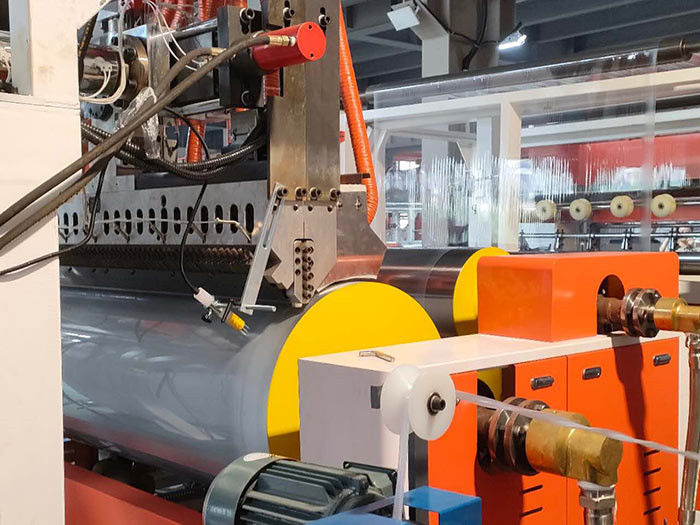

1500mm new type automatic high speed five layer co extrusion winding machine |

φ65/90/65 |

1 |

|

|

|

|

Cooling roll enlarged |

1 |

free |

|||

|

Static sewing machine |

1 |

free |

|||

|

International advanced Coupling |

3 |

free |

|||

|

Stainless steel automatic suction machine |

3 |

free |

|||

|

Automatic loading and unloading of gas expansion shaft |

3 |

free |

|||

|

Automatic loading and unloading device (automatic threading, unwinding, pumping and venting) |

1 |

|

|

||

|

Double negative pressure vacuum box (in vacuum, heat and mist are removed to improve quality) |

|||||

|

Automatic hydraulic screen changer (save network changing time and improve security) |

|||||

|

Remarks: |

The unit has passed CE quality certification, free installation and debugging, free technical support. Free warranty for 12 months. |

||||

一.Detailed technical parameters of the whole machine:

PRODUCT:PE STRETCH FILM

PRODUCT WIDTH:100-1500mm

PRODUCT THICKNESS:0.012-0.05mm.

RAW MATERIAL:LLDPE

LAYER:ACBCA

RATIO:25%/50%/25%(adjustable)

Maximum extrusion capacity of the whole machine (max):150-320Kg/h

Mechanical design line speed(max):200m/min

POWER:3P,380V,50HZ

WHOLE POWER:138KW

FILM ROLLER DIA:Φ300MM

Specification of paper tube core:INNER φ 76* ,OUTφ 96mm. *3

Machine dimensions (for reference only):L12500MM*W5500MM*H3800MM

Weight of the whole machine (for reference only):15T

二.SPECIFICATION:

1.SCREW BARREL(zhoushan)

2.MAIN MOTOR, 22KW & 45KW & 22KW

3.MAIN INVERTER“DELTA”BRAND, 22KW & 45KW & 22KW

4.HEAT: ALUMINUM COATING HEA(ENERGE SAVING, DURABLE);

5.TDIE 1850MM

6.PLC

7.Auxiliary engine "light rail electric"

8.The main engine adopts the mode of "American Martin coupling structure" (industry advanced technology). Stable and efficient. Mute. (energy saving)

9.The auxiliary engine adopts a new high-speed structure and "swing device"

10.The main gun barrel cover is free movable

11.The buffer adopts "induction cylinder"

12.The roll changing mode is "cylinder automatic roll up" (automatic cutter, automatic roll changing)

13.The first cooling roller is 720mm (using fog surface grinding roller, practical, exhaust, dewaxing)

14.AUTO LOADER ,3PC

15.FILM EDGE COLLECTOR DEVICE, 1PC

16.Temperature control system

17.Solenoid valve

18.Static sewing machine 1PC

三:Detailed specification of equipment

Equipment specification:

1.“A”EXTRUDER, 1 SET

(1)SCREW(zhoushan))

DIAMETER:φ65mm L/D RATIO 30:1

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT

(2)BARREL

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT ON INNER AND OUTER PART.

HEAT: ALUNIMUN COAT HEAT

COOL: FAN COOL IN LOW NOISE

(3)EXTRDER GEARBOX ZLYJ SERIES, WITH FORCED LUBRICATION

(4)MAIN INVERTER 22kw WITH MOTOR 22KW

2.“B”EXTRUDER, 1 SET

(1)SCREW(zhoushan)

DIAMETER:φ90mm L/D RATIO 30:1

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT

(2)BARREL

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT ON INNER AND OUTER PART.

HEAT: ALUNINUM COAT HEAT

COOL: FAN COOL IN LOW NOISE

(3)EXTRDER GEARBOX ZLYJ SERIES, WITH FORCED LUBRICATION

(4)MAIN INVERTER 45kw WITH MOTOR 45KW

1.“C”EXTRUDER, 1 SET

(1)SCREW(zhoushan)

DIAMETER:φ65mm L/D RATIO 30:1

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT

(2)BARREL

MATERIAL:38CRMOALA WITH NITRIDING TREATMENT ON INNER AND OUTER PART.

HEAT: ALUNIMUN COAT HEAT

COOL: FAN COOL IN LOW NOISE

(3)EXTRDER GEARBOX ZLYJ SERIES, WITH FORCED LUBRICATION

(4)MAIN INVERTER 22kw WITH MOTOR 22KW

四、Coextrusion distributor

1、Hierarchical distribution: ACBCA

2、Heating mode: stainless steel heating tube is used.

3、Electrothermal capacity:12.5KW,380V.

4.The ACBCA distributor of shunt mandrel is phase block adjustment.

五、TDIE:

1.PRODUCER:taizhou huangyan

2.WIDTH:1850mm

3.MATERIAL:718Die steel

4. die head structure: (insert type heating pipe is in the middle, and it is totally closed, and the connector of aviation pole socket type)

5.Electrothermal capacity:25kw

六、WINDER

1. Cooling setting roller 2

Roller specification: φ 720mm*1950mm, φ 370mm*1950mm

Cooling system: spiral flow channel, ultra - fine grinding, electroplating hard chromium, cooling water cooling

Cooling roller process: all rollers are dynamically balanced to ensure smooth film discharge

2. Winding traction roller 2

Roller specification: φ 420mm*1700mm。

3. Hard aluminum wheel: ¢ 90mm x 1850mm x2 sets

4. Rubber roller: ¢ 90mm x 1850mm x2 sets

5. Unfolding guide roller: ¢ 90mm x 1850mm x2 sets

(all rollers are dynamically balanced to ensure smooth film discharge)

七、Electrical control

1、Extruder control cabinet 1

2、Coiling control cabinet 1