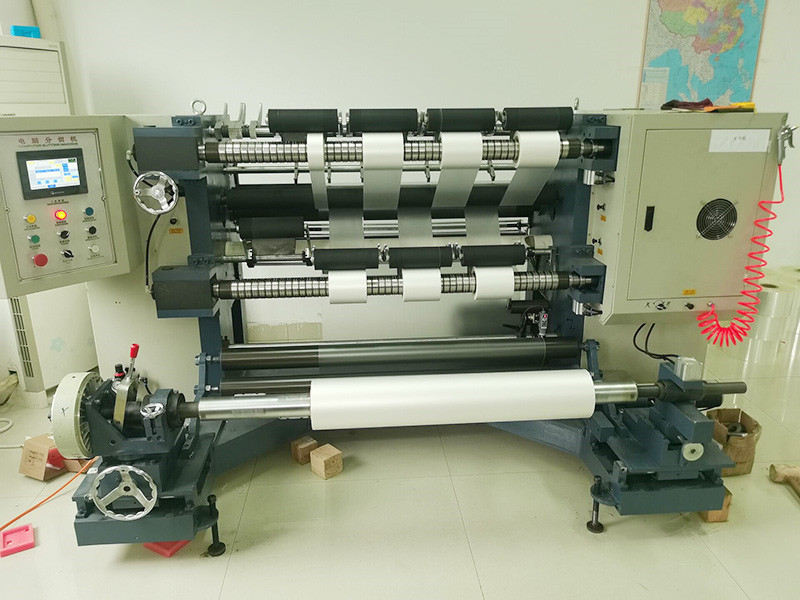

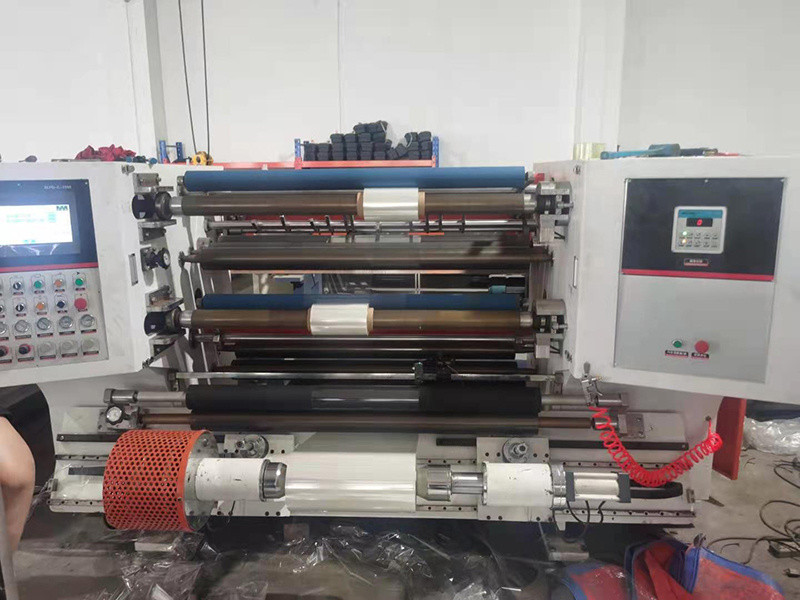

1. Machine details:

|

No. |

Main data |

parameters |

unit |

remark |

|

1. |

Suitable material |

Roll paper/BOPP/CPP/PET/PE/Soft aluminum composite film / aluminum coating and other drum materials. |

||

|

2. |

Material thickness |

0.012--0.3 |

mm |

|

|

3. |

width |

1300 |

mm |

|

|

4. |

Roller length |

1350 |

mm |

|

|

5. |

Unwind diameter |

800(MAX) |

mm |

|

|

6. |

Rewind diameter |

500(MAX) |

mm |

|

|

7. |

Machine speed |

200 |

m/min |

Material decide |

|

8. |

Tension range |

5—200 |

N |

|

|

9. |

Unwind tension control |

Constant tension |

|

|

|

10. |

Rewind tension control |

Taper tension |

|

|

|

11. |

deviation method |

Heel side |

|

|

|

12. |

deviation accuracy |

±0.3 |

mm |

|

|

13. |

Deviation correction stroke |

±70 |

mm |

|

|

14. |

Coiling mode |

Central coiling |

|

|

|

15. |

Feeding mode |

The air expansion shaft rolls up and the air cylinder rises and falls |

|

|

|

16. |

Discharge mode |

The winding shaft can be unloaded by rotating, the shaft is not unloaded, and the material can be pulled out (or can beunloaded together by the shaft, dual use) |

||

|

17. |

Unwinding paper core |

3($76) |

Inch(mm) |

Paper tube |

|

18. |

Rewinding core |

3($76) |

Inch(mm) |

Paper tube |

|

19. |

Raw material cutting width |

100-1300 |

mm |

|

|

20. |

Meter accuracy |

±1/1000 |

m |

|

|

21. |

Unwinding tension device |

100 |

N.M |

|

|

22. |

Winder tension device |

50 |

N.M |

|

|

23. |

Traction power |

5.5 |

Kw |

|

|

24. |

Edge blowing power |

0.75 |

Kw |

|

|

25. |

Total power |

7 |

Kw |

|

|

26. |

Voltage |

AC 380±5%,50HZ |

V |

3 phase 5 line |

|

27. |

Air Pressure |

8 |

Mpa |

|

|

28. |

Machine color |

white |

|

|

| 29. |

Control panel color |

black |

|

|

| 30. |

Safety protection color |

yellow |

|

|

| 31. |

Machine size |

L1800xW2800xH1750 |

mm |

|

| 32. |

weight |

=2500 |

Kg |

|

2、 Function description

Unwinding section

Unwinding mode: the material coil adopts axial pneumatic lifting.

Unwinding and deviation correction: the machine adopts domestic analog deviation correction system to track material edge.

Deviation adjusting device: the unwinding aluminum guide roller is equipped with longitudinal deviation adjusting device, so that the material can run parallel to the guide roller to the maximum extent, ensuring the winding accuracy and quality.

Unwinding tension detection: Hall switch, cooperate with magnetic powder brake to realize unwinding tension. The unwinding warp is detected by Hall switch, the output torque is calculated, and the tension is automatically calculated by PLC.

Unwinding control: the machine has the functions of start-up, stop, speed regulation, alarm of unwinding surplus material and unwinding tension adjustment, which are matched with the rewinding place and synchronized with each other, and has the display of host speed and unwinding tension.

Traction device

Traction drive: traction roller is driven by frequency conversion motor and synchronous belt.

Traction roller: after dynamic and static balance correction, the traction roller has stable operation and no vibration source, which is suitable for a wider range of materials and high-speed applications.

Traction pressure roller: rubber roller is selected as the material of traction pressure roller. After dynamic and static balance correction, pneumatic control is adopted for the lifting of traction pressure roller, and the pressure is adjustable.

> meter counting: the coding wheel is used to detect the working length, which has the advantages of high precision and high resolution. Considering the requirements of production process, the program design has the functions of cumulative meter counting and automatic stop when the number arrives.

"Professional slitting machine manufacturer"

Slitting device:

Cutting mode: round knife + straight knife cutting.

> number of turrets: round turret + straight turret, 10 standard.

Transition guide roller: transition transmission aluminum roller, with diamond cross line on the surface, making the material more smooth and comfortable in the process of high-speed operation.

Waste edge device

> edge material treatment: the waste separation mode of this machine adopts the suction form. When the edge material is separated from the slitting knife, the guide wheel will separate the edge material from the inside of the machine to the outside of the machine, and the direction of the waste edge port is located on the left side of the machine.

Winder

Winding mode: 3-inch air expansion shaft to realize automatic tension control.

Winding drive: magnetic powder clutch, automatic taper tension control and synchronous belt drive are adopted for winding tension control

Back pressure roller: the contact pressure roller is controlled by air cylinder, the pressure of contact roller is controlled by precision pressure regulating valve, the contact pressure roller is rubber roller structure, and the air pressure can be adjusted according to the winding requirements.

Electrical and pneumatic devices

Drive: the drive part is driven by high-performance variable-frequency motor and controlled by matching variable-frequency controller

System to achieve high precision speed.

"Professional slitting machine manufacturer" > control: the host is controlled by PLC program, and the man-machine interface is used to set the operation parameters and monitor the operation status.

Interface: touch screen human-machine interface

Other configurations:

The machine adopts high strength and low stress steel wallboard with thickness of 30mm. The stability of the wallboard is good after secondary stress relief.

All rotating parts of the machine adopt domestic famous bearings.

The mechanical parts of the machine are processed by the machining center and CNC machine tools.

Emergency stop button and emergency pull switch are installed at the operation position of the machine.

Brand and model of main components:

|

No |

Name of Components |

Model of components |

Number |

brand |

|

1. |

Rectifying device |

|

1 |

dongdeng |

|

2. |

Round and straight knife |

|

10 |

china |

|

3. |

Unwind powder brake |

100N.M |

1 |

shengda |

|

4. |

Hall sensor |

|

1 |

china |

|

5. |

Traction motor |

YS100A5P5 |

1 |

shanghai |

|

6. |

Roller clutch |

50N.M |

2 |

shengda |

|

7. |

Driver inverter |

HY series |

1 |

shanghai |

|

8. |

Trimming fan |

JH |

1 |

china |

|

9. |

Touch screen |

MT series |

1 |

Kunlun tongtai |

|

10. |

PLC and module |

XMZ series |

1 |

siemens |

|

11. |

Cylinder and solenoid valve |

|

1 |

AirTAC |

|

12. |

Cylinder |

CHD2F series |

2 |

china |

|

13. |

bearing |

|

1 |

china |

|

14. |

Rubber roller |

|

|

china |

|

15. |

Aluminum roller |

|

|

china |

2. Spare parts

|

no |

name |

|

Quantity |

Unit |

|

1 |

Oil pot |

|

1 |

pc |

|

2 |

Open end wrench |

8-10 |

1 |

pc |

|

3 |

Open end wrench |

12-14 |

1 |

pc |

|

4 |

Open end wrench |

17-19 |

1 |

pc |

|

5 |

Open end wrench |

22-24 |

1 |

pc |

|

6 |

inner hexagon spanner |

1.5-10 |

1 |

Set |

|

7 |

A screwdriver |

|

1 |

pc |

|

8 |

Cross screwdriver |

|

1 |

pc |

FAQ

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q: How do you make your price?

A: We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacturer.You will get competitive price and high quality.

Q: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More important, we put a high value on our reputation. High quality is our principle all the time. You can be assured on our production completely.

Q: How long does the whole procedure being worked out?

A: After you place an order,for small quantity 15-20 days is enough,for big quantity,we can talk further.

Q: What about the transportation and delivery date?

A: Normally we use sea way for shipment to save customer's money.It is about 25-40 days.It also depends on which country and port you are. If there are some emergencies we can send the goods by air,or by international express, as long as you afford the traffic expense.

Q: Are we still need to install the machine after we got?

A: We will adjust the machine before we deliver to you, also we will send you video and manual to teach you how to use the machine.