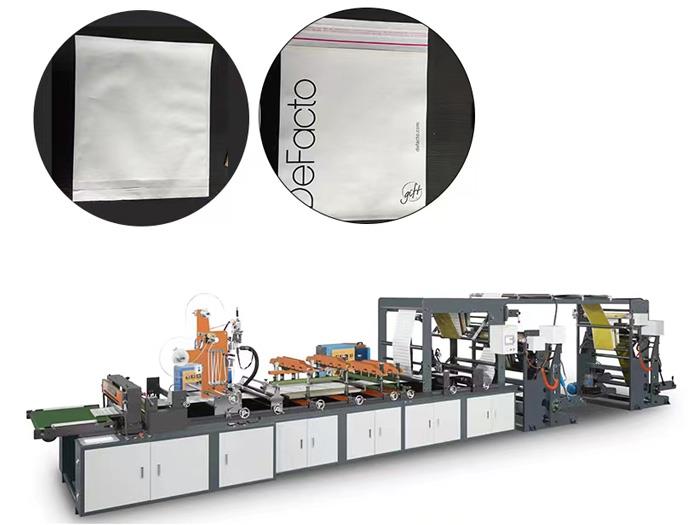

Ⅰ. Description

This machine is specially developed for making transparent paper three-side sealing clothes bags by on-line gluing. The machine uses two rolls of pure paper material, which is glued and sealed online, from paper unwinding to finished product are completed at one time. The finished bag is flat andgood looking, the equipment operation is simple and easy to learn, and it is a high cost-effective equipment.

Ⅱ. Technical parameters:

1. Suitable material: every kinds of paper roll.

2. Maximum mechanical speed: 60 pcs/min, small bags can make in two lines.

3. Maximum bag width:600mm

4. Maximum bag length:750mm

5.Maximum unwinding diameter:φ1200mm

6.Maximum unwinding width:750mm

7.Overall Dimension:Length 12.5m Width 1.8 m and height 2 m

8.Power required: AC three phase five lines 27KW

9.Steel board machine body

10.Air pressure: constant pressure over 6 kg/cm²

Ⅲ. Equipment Configuration:

1.Main control

PLC as main control, 10 inches human machine interface,two servo motors system,separately control the fixed length, crosswise applying glue, glue gun holding roller lifting and the cutter movements.

2.Apply glue part

This machine is equipped with 2 sets of hot melt glue machine, one is for applying the hot melt glue on the bag flap,and is also equipped with two lines release paper unwinding and glue applying device.(can make in two lines when bag height is less than 350mm.) The other one is the two outputs glue machine, it is used for apply glue crosswise and lengthways on the bag three sides. The crosswise applying glue was driven by servo motor, and can drive the glue gun to apply glue according to the set length. The other glue gun is for applying glue on the bottom of glue lengthways.

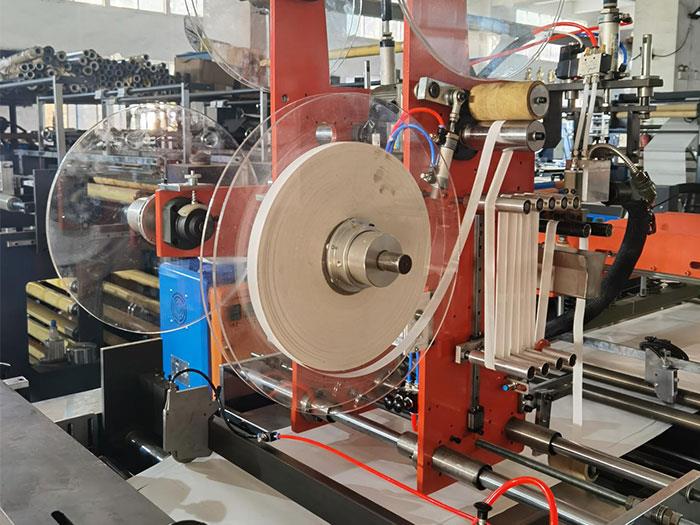

3. Unwinding part

There are two independents unwinding rack, both equipped with automatic magnetic powder tension brake, computerized deviation rectify, hydraulic lifting material device. The unwinding shaft is three inches air shafts.

4.Sealing part

This machine is equipped with two sets of crosswise sealing knifeand one set of lengthways sealing knife. Both have heat sealing knife and cooling knife.The knife width is 20mm( can customize as customer’s requirement).

1. Electric eye tracking

Equipped with Taiwan made Kontec sensor

2. Cutting part:

Equipped with wear-resistant high-speed steel cutter, Torsional shearing device, and equipped a cutter as spares at the same time.

7.Receiving part:

There are moving receiving belts and the receiving table, and the products are transported to the receiving plate by the conveyor belt.

Ⅳ. Supporting facilities:(The buyer supply)

1.Power: 3-phase 4-wire AC380V 50Hz and ground earth (notes: The steel diameter must be 30-50mm, the length is more than 1.5m directly put into the ground, and there should be a line conductor which more than 4 square mm leads to upside of ground)Strictly forbid the null line connecting the machine.

2. Installation filed: The buyer must make sure the ground is hard enough to support the machine run stably after installation and debugging. And to avoid the ground settlement that make the machine work abnormal or broken.

3. Air pressure:5 kg/cm² constant air pressure

4.Power required:AC THREE PHASE FIVE WIRE 380V 50Hz,50KW