Main technical parameters:

1.Unwinding maximum diameter 600 mm (cylinder core 76 x 95)

2. Maximum width of unwinding 1100mm

3. Maximum diameter of winding 450 (cylinder core 76 x 95)

4. Rewinding width 30-1100mm

5. Maximum slitting speed 200 m/min (depending on material)

6. Slitting Thickness 10-75 um Flat Cutter Slitting

7. Slitting accuracy (+0.3mm)

8. Total power is about 6 kW

9. The weight of the machine is about 1700 kg.

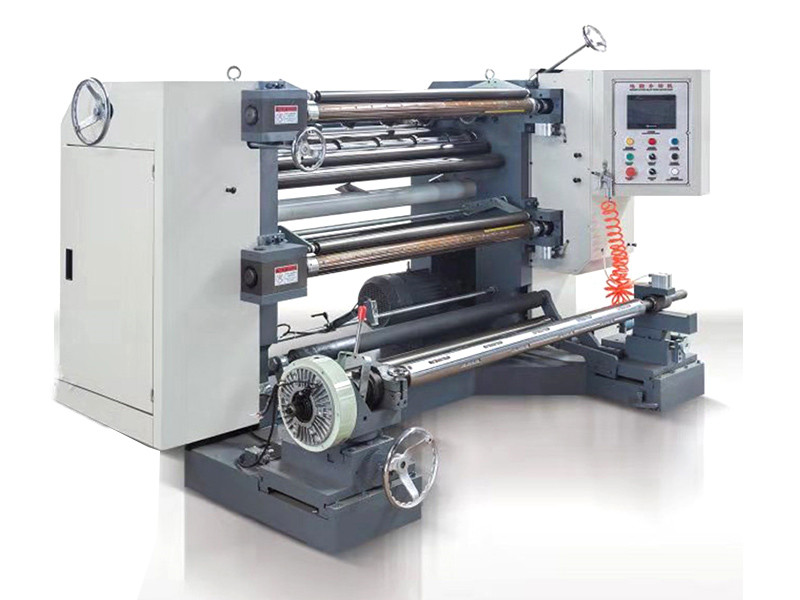

10. Machine outline size (length * width * height) 1500 * 2840 * 1560 (mm)

II. Explanation of Main Parts:

1. Rewinding Department

(1) Structure

A) Rewinding is in the form of passive rewinding with magnetic powder brake.

B) The air expansion shaft is used to install the coil. Photoelectric automatic deviation rectification system is used for feeding and rectifying deviation. Slitting accuracy (+0.3mm)

(2) Specification

A) Maximum width of drum material 1150 mm

B), magnetic powder brake specification 50N.M

C) Rectifying Motor 110TDY115-1 Permanent Magnet Low Speed Synchronous Motor

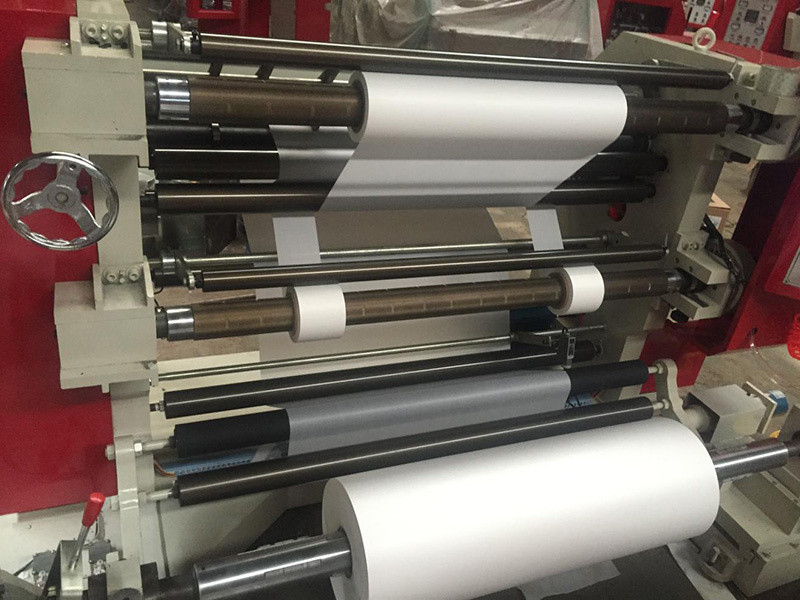

2. Traction Department

(1) Structure

A) Double roll phase pressure drives the cutting process. The active roll is steel roll and the pressing roll is rubber roll.

B) The traction roll is driven by a motor and the cutter is driven by a synchronous wheel.The reel rotates.

(2) Specification

A), diameter of traction roll and pressing roll 119mm

B) Main motor Y100L2-4w three-phase asynchronous motor P=4kw

C) Inverter 4kw

3. Partition

(1) Structure

A) Flat cutter cutting: The lifting and landing of the cutter rack is regulated by worm wheel and worm.

(2) Specification

A). Diameter of cutter roll under flat knife 90

B) Standard single-sided blade for flat top knife

4. Rewinding Department

(1) Structure

A) The reel is a double-position inflation shaft.

B) The reel is driven by the main motor through synchronous pulley and magnetic powder clutch.

C) Rolling rollers adopt positive section type to ensure the neatness of rolling.

(2) Specification

A) Maximum winding diameter 450mm

B), winding width range 30-1100mm

C) Rewinding paper core 76 *92

III. Major Control Elements

1. Electrical Control System Kodak Industrial Control Set

2. Rewinding Tension Shengda Magnetic Powder Brake (50N.M) 1 Set

3. One domestic three-phase asynchronous motor (4kw) for main motor

4. Inverter Shenzhen Yingweiteng 4kw)

5. Winding Tension Shengda Magnetic Powder Clutch (50N.M) 2

6. Deviation Correction Controller Ryan Kodak Industrial Control Company 1 Set

7. Pneumatic Components Taiwan Joint Venture Dongte Full Set

8. Three sets of air-swelling axles in Shanghai

9. Fan Taizhou Manda 0.75 kW 1

10. Aluminum rods made in Shanghai (brown dynamic equilibrium oxidation) have 806 diameters

11. The transmission part is driven by synchronous belt.