Technical indicators and main parameters:

|

Model |

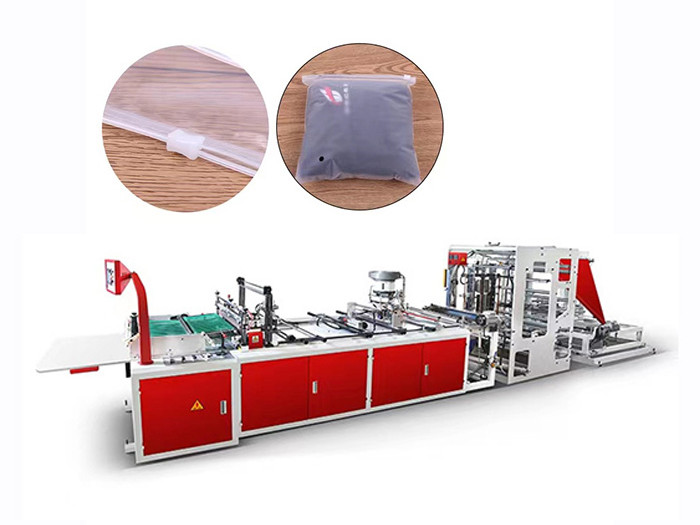

MD-800 high speed PE automatic zipper machine |

|

Machine speed |

20~150pcs/min |

|

Bag width |

50~700mm |

|

Bag length |

50~700mm |

|

Bag making thickness |

3~10 |

|

Voltage |

220v/380V |

|

Total power |

9kw |

|

Overall dimension |

8000×1300×1900mm |

|

Weight |

2080KG |

|

Knife |

It is equipped with a set of hot zipper forging copper knife, a set of bag cutting forging imported steel knife and a set of cold knife |

|

Unwinding diameter |

600mm (with automatic deviation correction, automatic magnetic particle constant tension, automatic feeding and automatic shutdown without material) |

|

Pneumatic punch |

Round hole1 pc |

|

Conveyor belt |

Imported Kodak brand |

|

Automatic photoelectric tracking |

Imported from Germany |

|

Electric control system of the whole machine |

Special multi motor tension drive system stepping motor Songyang brand (servo motor can be used) |

|

Variable frequency reduction motor |

Guangdong Wanxin |

|

Relay |

欧姆龙OMRON |

|

Pneumatic components |

Yadeke, Shenzhen, etc |

|

Automatic make-up vibrating plate |

广东 Guangdong |

|

Ultrasonic bag mouth flattening reinforcement |

广东Guangdong |

|

Temperature display instrument |

Thermometer made in Shanghai for displaying the surface temperature of preheating roll |

|

Common electrical components / switches |

Chint electric |

|

Frequency converter |

Changsha beishide |

|

Computer touch screen |

Taiwan Weilun |

|

PLC |

Mitsubishi |

|

Variable frequency motor |

Shanghai Suchuan |

|

Bearing |

Mostly imported from Japan |

|

List of free accessories |

1 temperature control line, 1 high-temperature cloth, 50 springs, random accessories, a set of toolbox, an oil gun, 1 temperature control meter, 1 heating tube and 1 switch. All instructions of this machine. Application: it is applicable to the automatic zipper bag of PE, PP, OPP, BOPP and other plastic materials, and the packaging of knitting, clothing, food, stationery and so on. It is an advanced bag making equipment instead of imported similar products at present. |