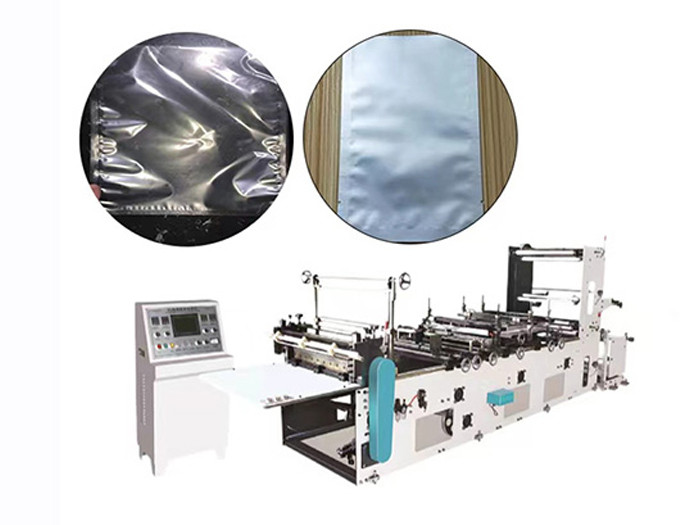

Configuration:

|

Mechanical part |

Electrical part |

|

1.Unwinding device: one unwinding edger, one ordinary unwinding rack, fixed with cone sleeve

manual lock |

1.Thehostadoptsvariablefrequencyspeedregulation (1.5kw), and the inverter uses Hualan |

|

2.Frame: 10mm steel plate structure |

2.one servo motor (Delta) for feeding |

|

3.Cross-cutting knife holder: using casting structure |

3.Traction uses two pcs 0.75KW inverter motors |

|

4. Cross-cutting knives: using domestic common cutters |

4.Photoelectrictrackingandpositioningdevice(Zhejiang Julong) |

|

5. Drive shaft: grooved by rubber shaft 6. Hot knife:Usecopper knife (2 two horizontal irons, 2 vertical irons) |

5.Independentmicrocomputercontrolcabinet: Automatic counting, automatic alarm when the number is reached. Automatic stop function |

|

7.Feeding traction method: the motor drives the pulley to drive the traction rubber shaft (Two traction rubber rollers and two discharge racks) |

6.Computer (touch screen control) |

|

8.Max bag width is 1000mm Max bag length is 600mm |

7.The host uses a motor 1.5KW with a reduction motor (Shanghai) |

|

9. Machine weight: 1700kg |

8.Mechanical speed: 120 pcs / min |

|

Dimensions: length 4.5 meters * width 1.2 meters * height 1.8 meters |

|